Hazelwood Horizon

2017, in collaboration with Anthony Nitche

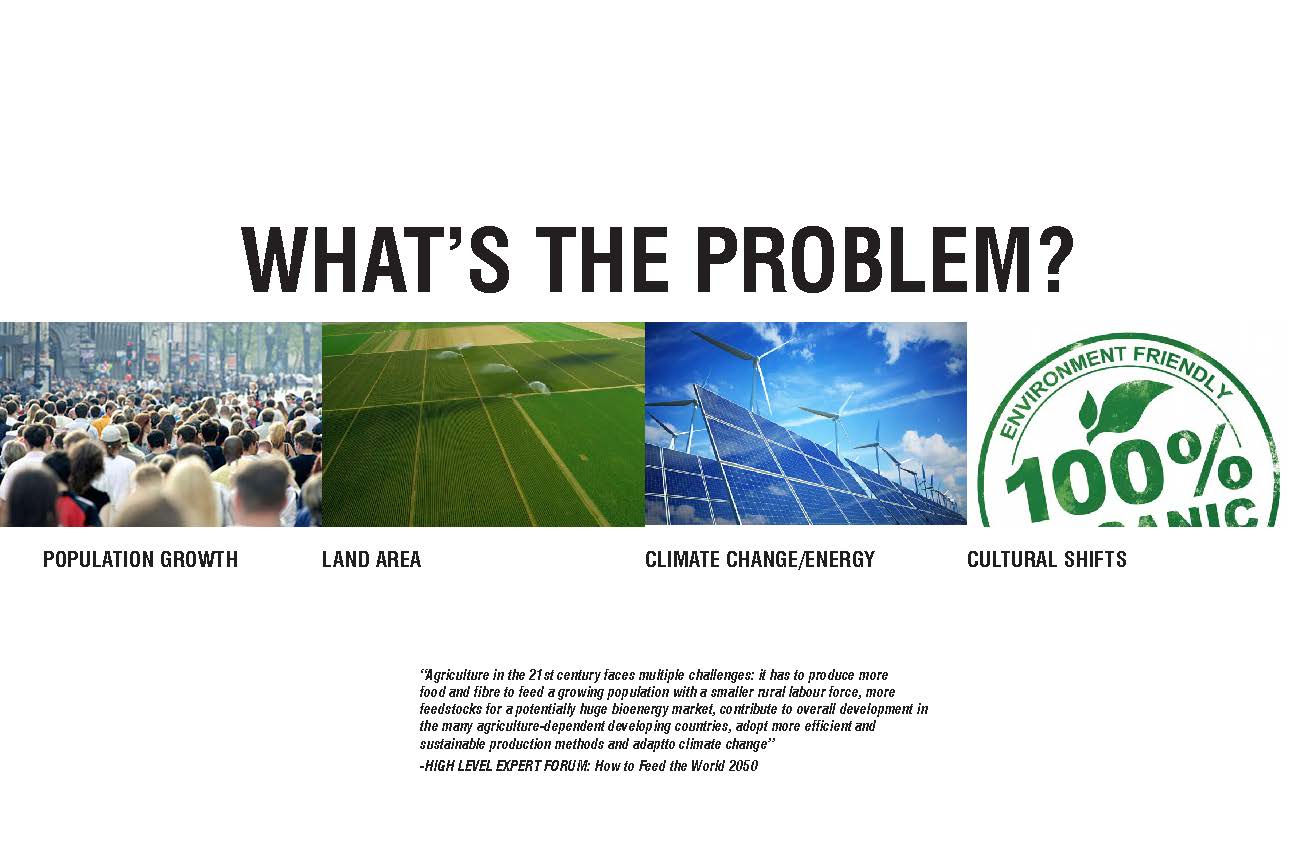

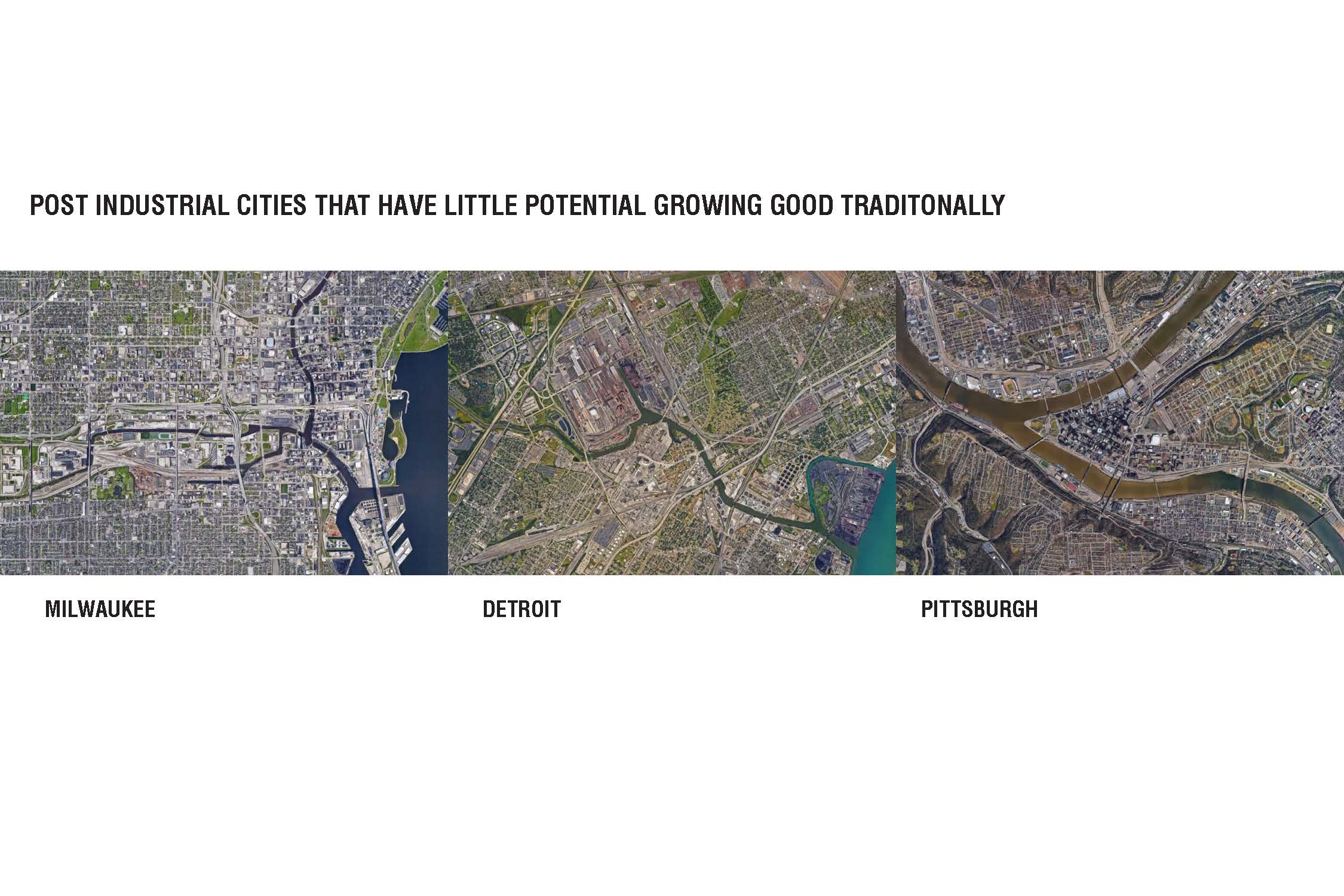

Situated on a historic steel production facility in post-industrial Pittsburgh, the project aims to revitalize the presence of manufacturing industry within an urban context. It is an antithesis of the outdated automobile-centric planning strategy that compartmentalized cities and silently became the foundation of our current political and social structure. We directed design proposals in collaboration with real manufacturing partners to brainstorm our goals and strategies, all while questioning how our architectural interventions would manifest in human and city scale. Our project, Hazelwood Horizon, focuses on the emerging agriculture technology - or AGTECH - industry, and aims to manufacture products that aid new farming techniques used to grow on-site produce.

PHASE 1: RESEARCH, INQUIRY & SITE

What defines a factory in the 21st century? And how do you propose designs that align with contemporary trends in manufacturing without ignoring the historic significance of factories?

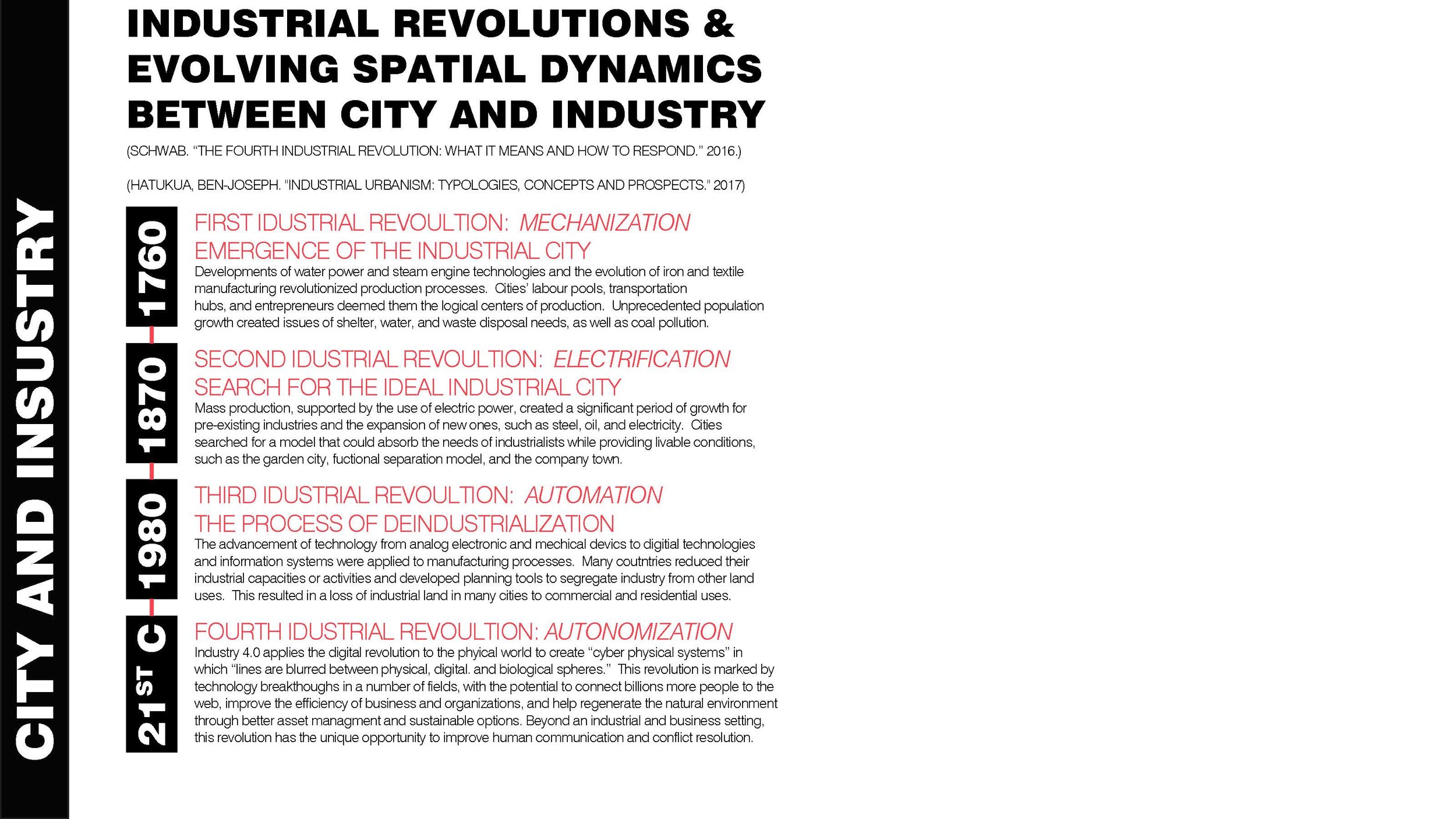

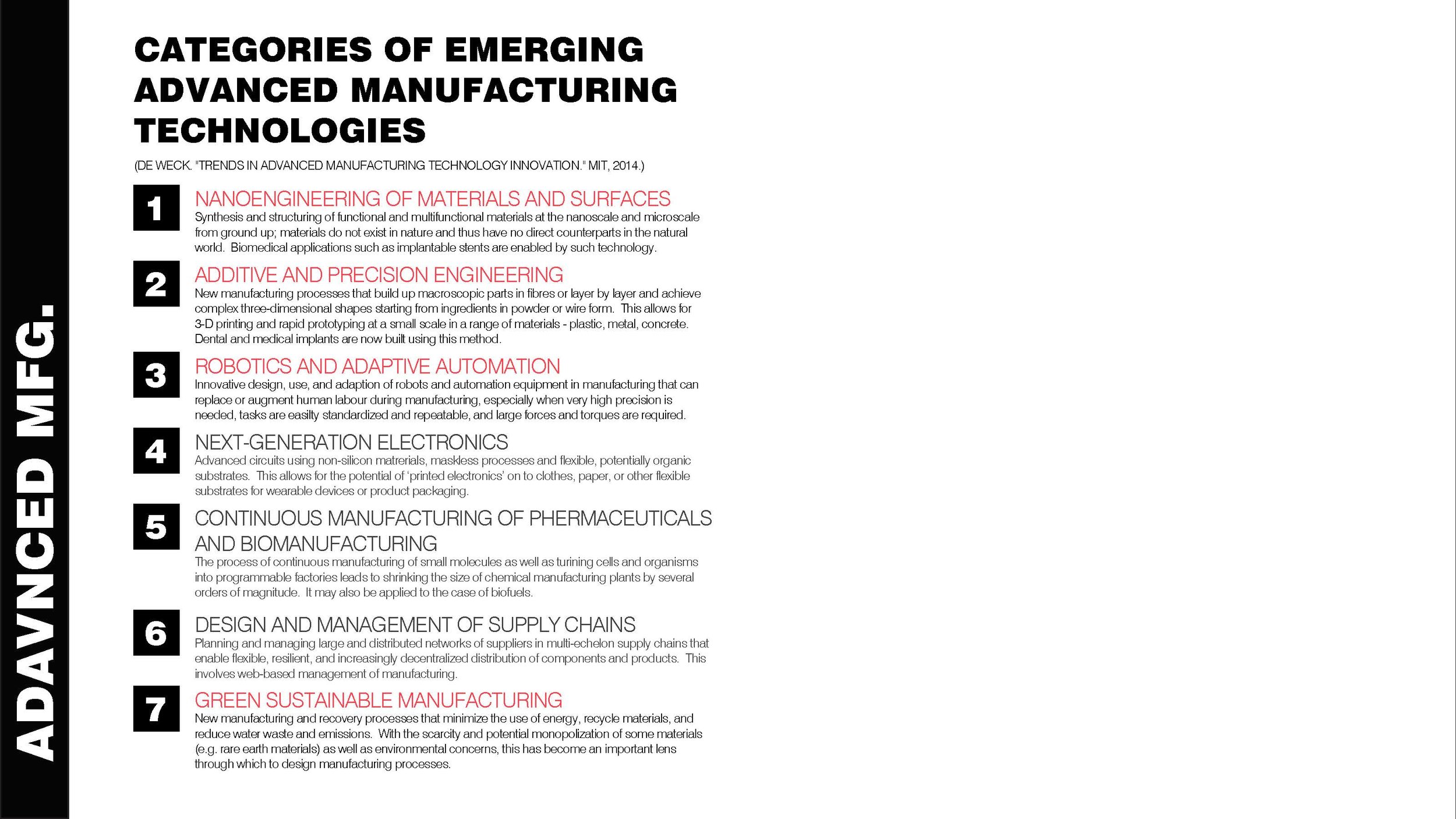

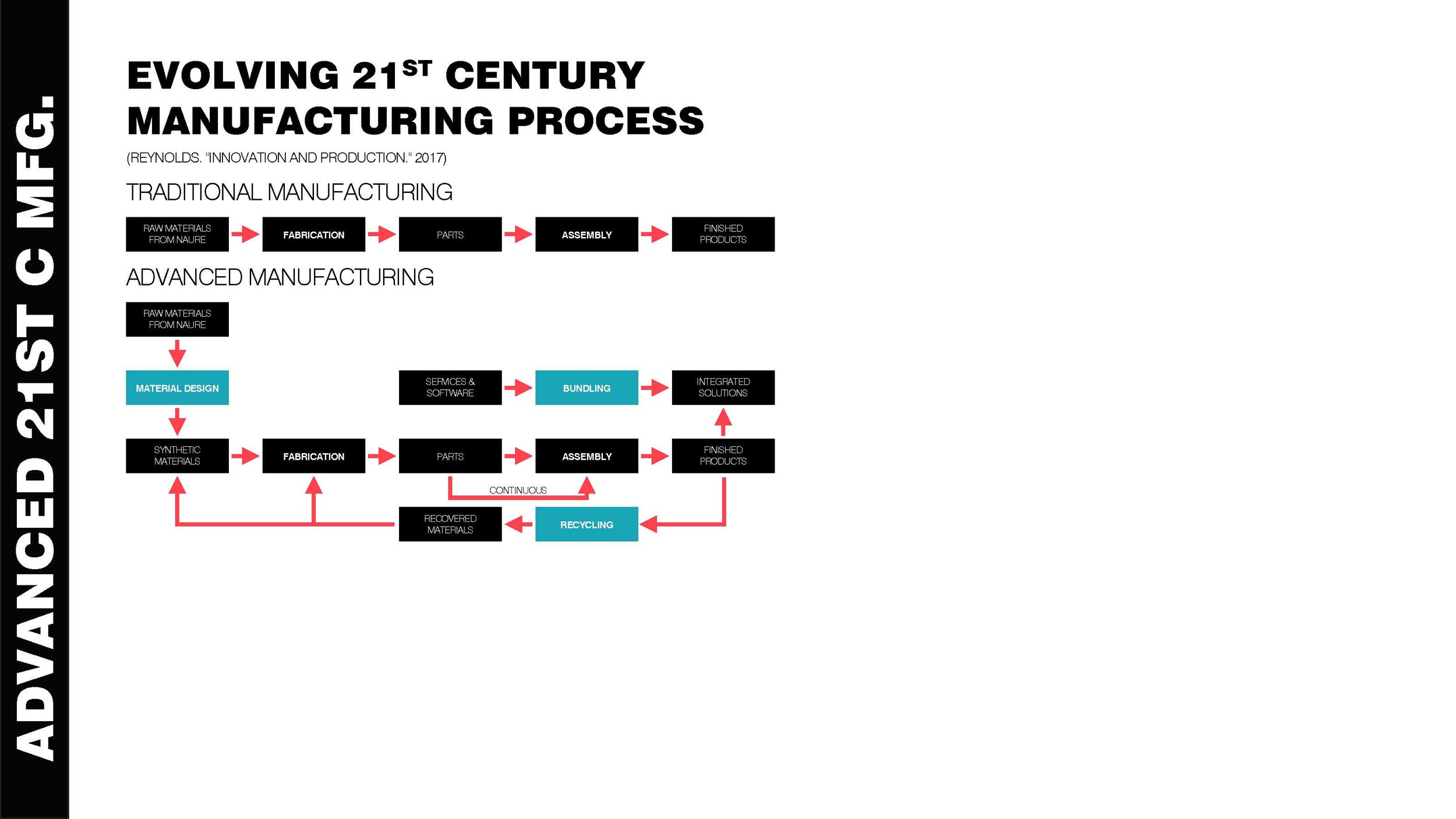

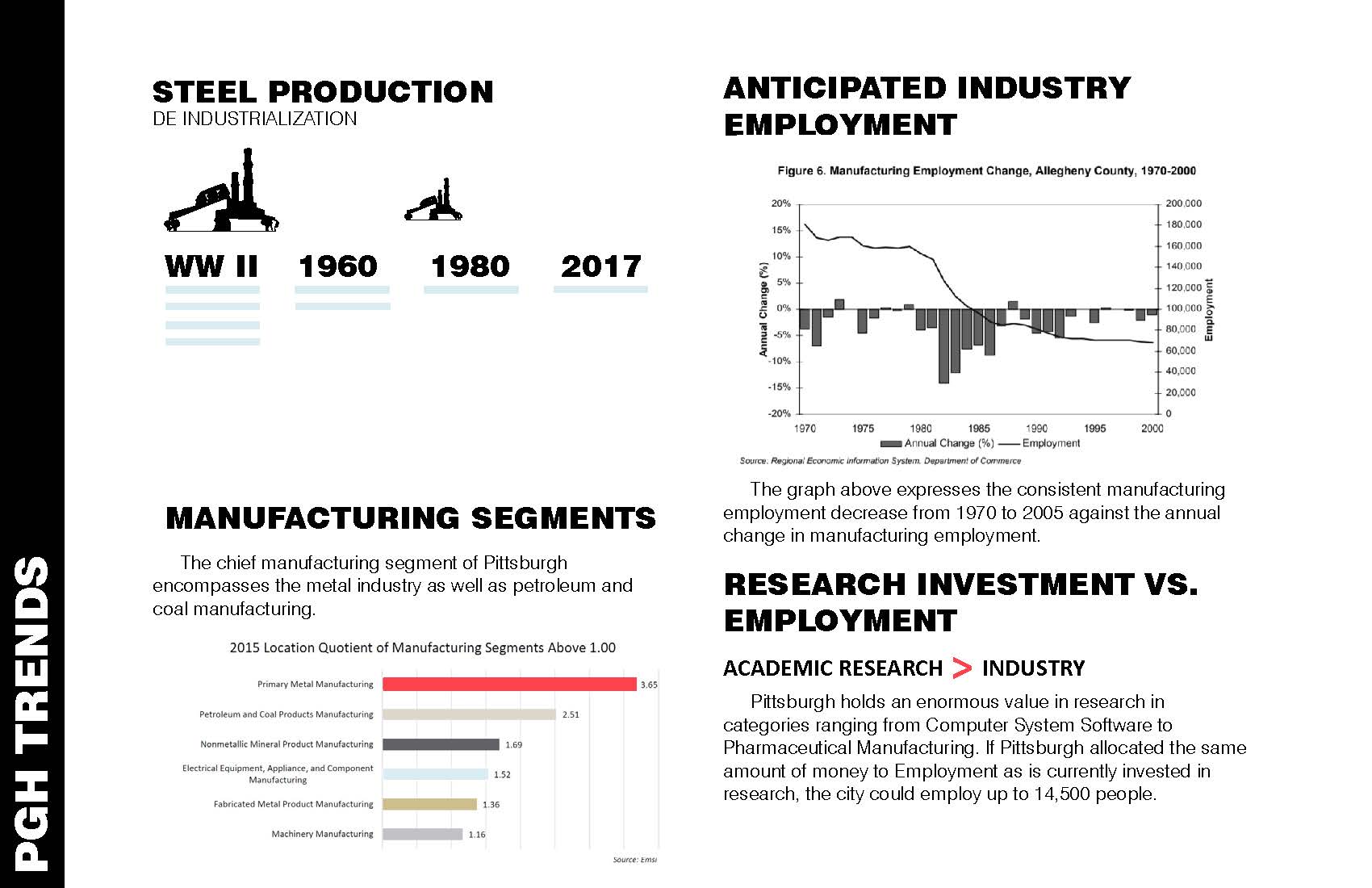

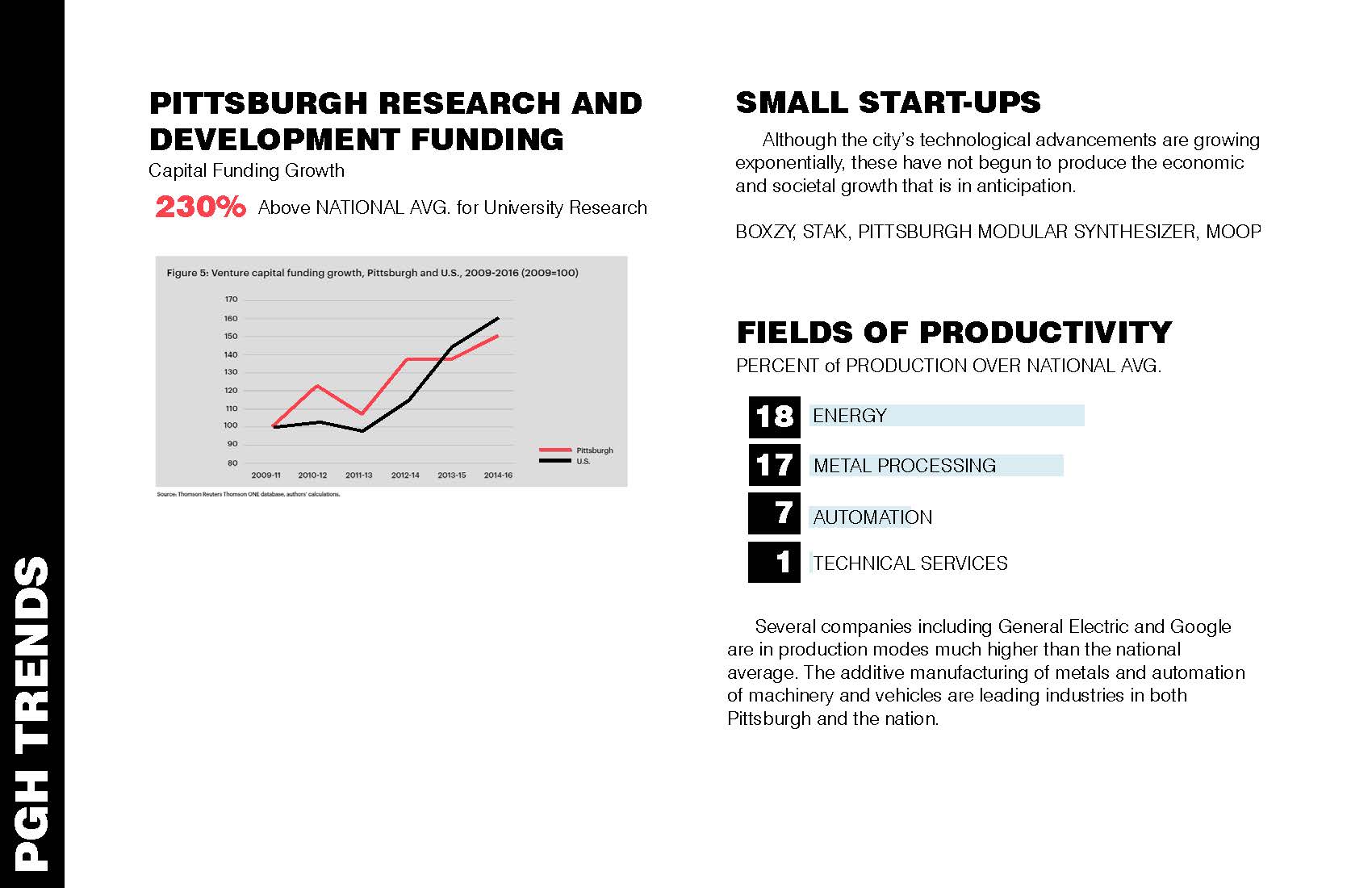

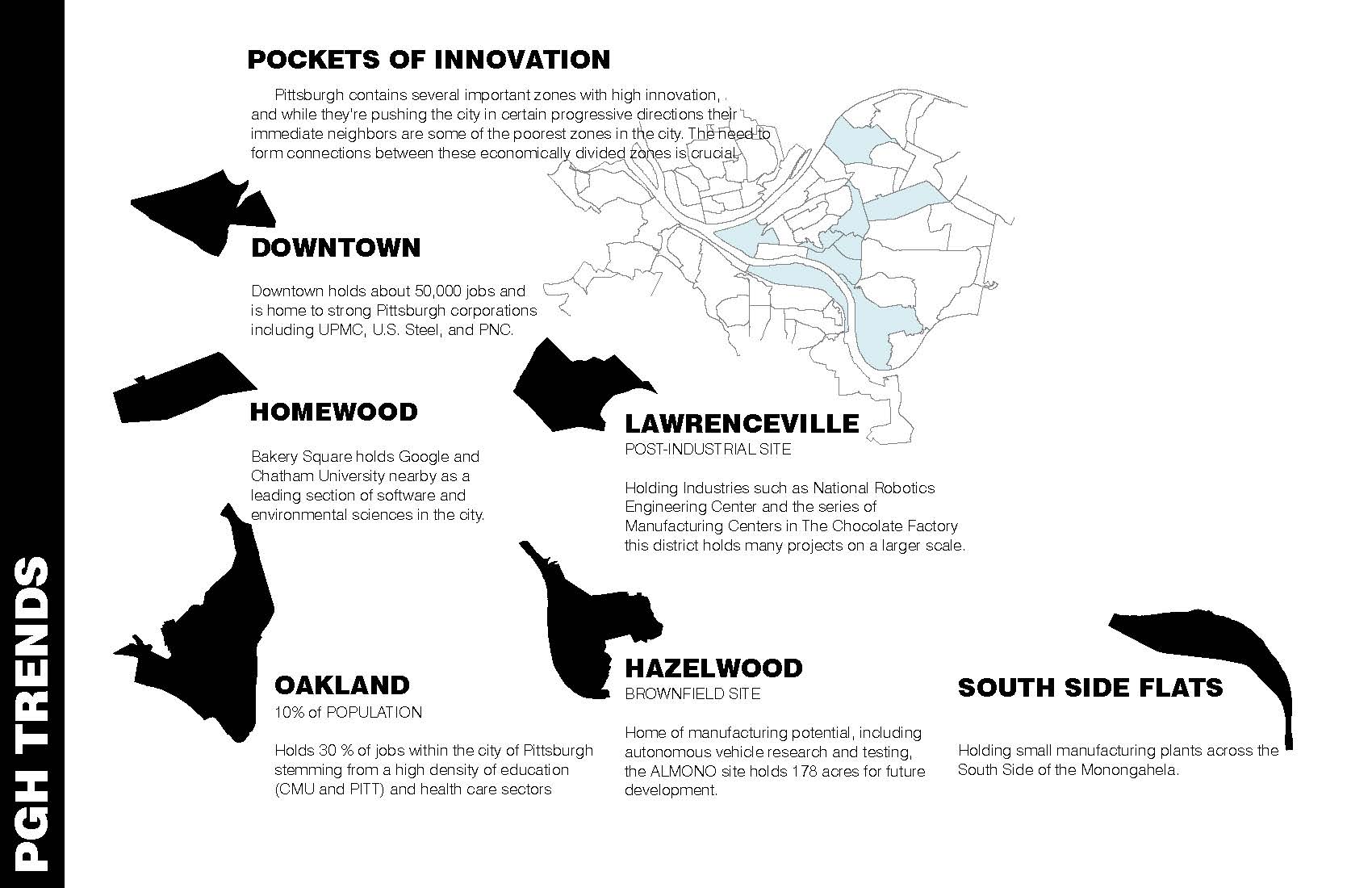

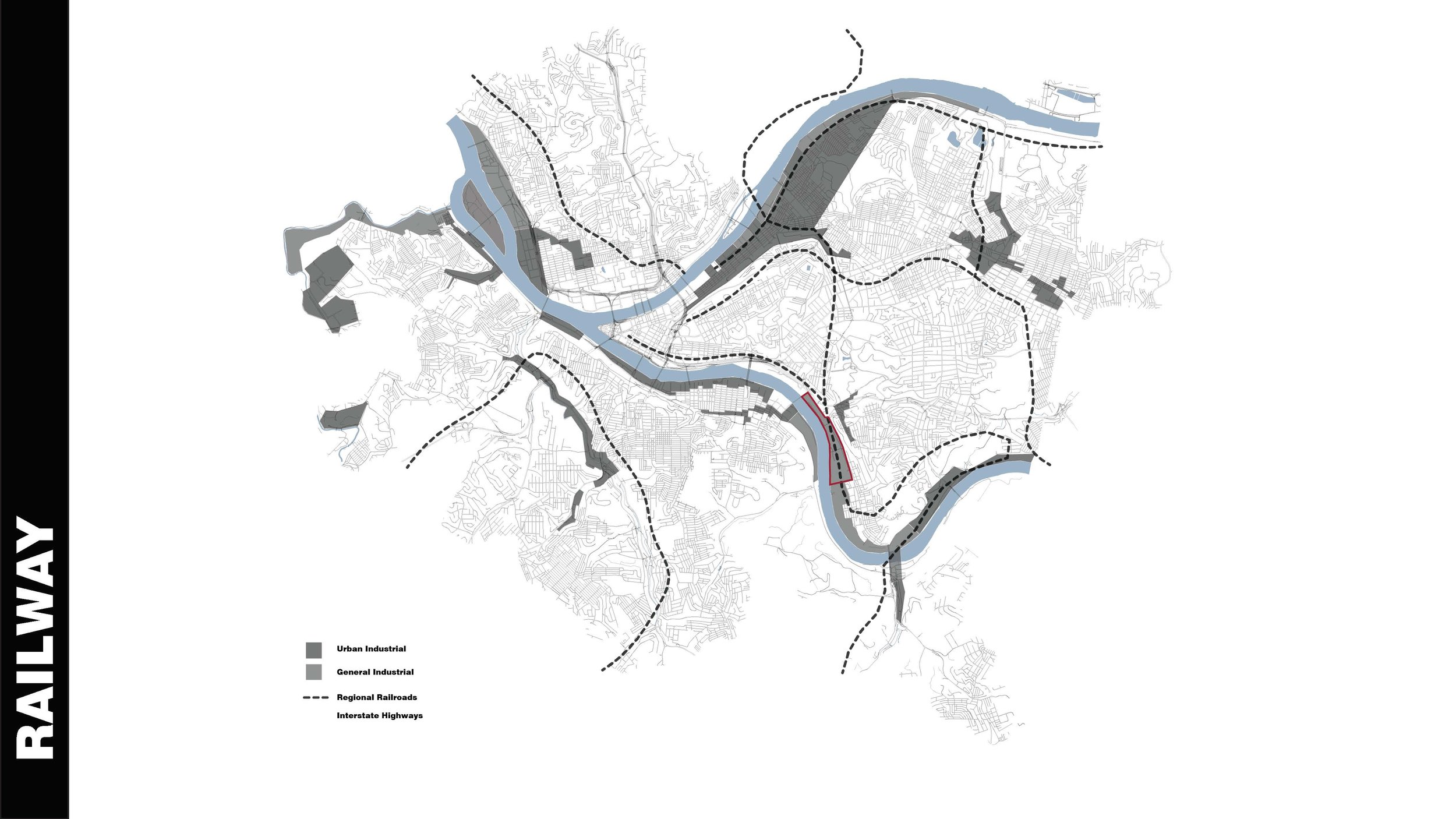

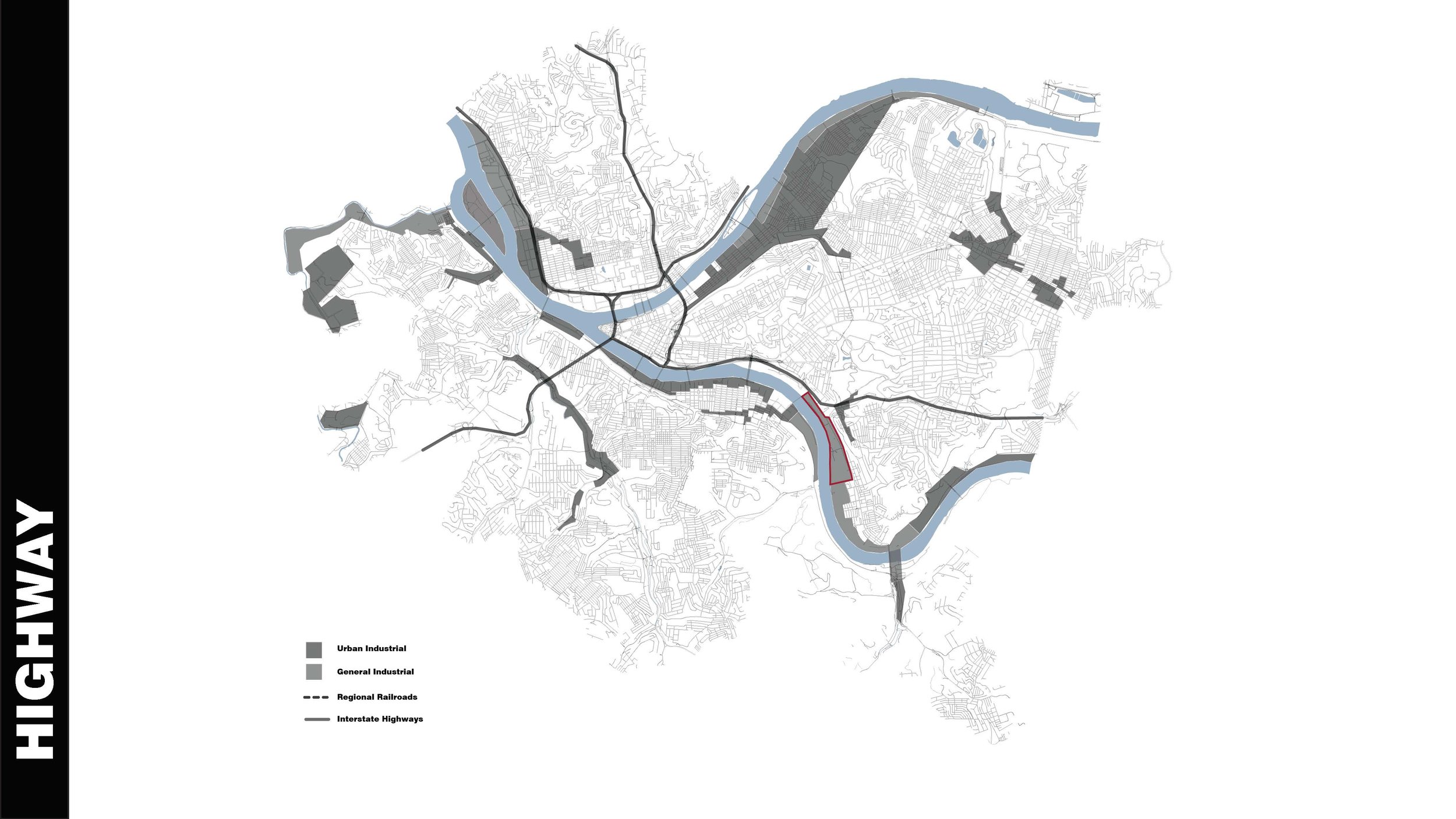

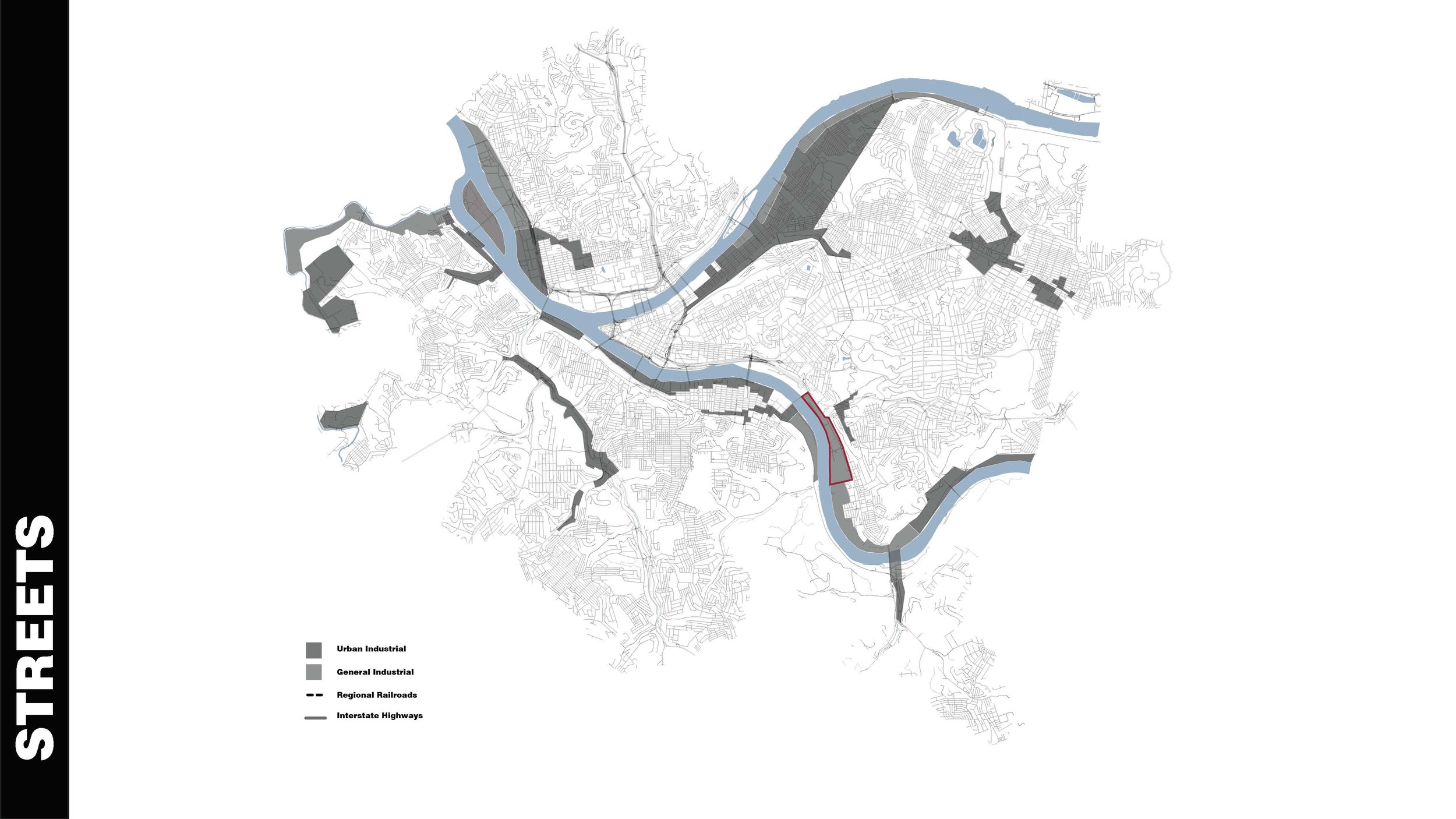

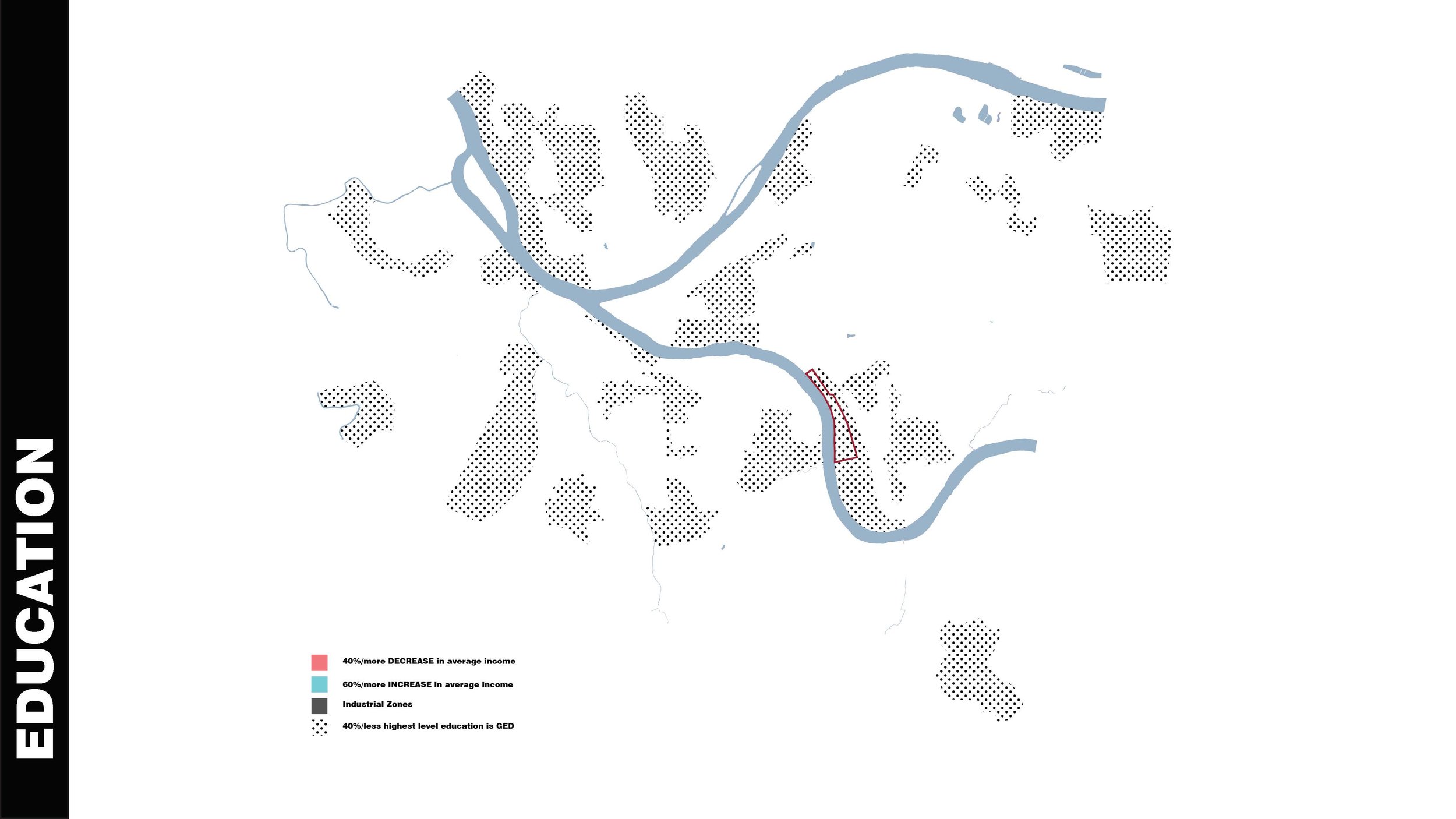

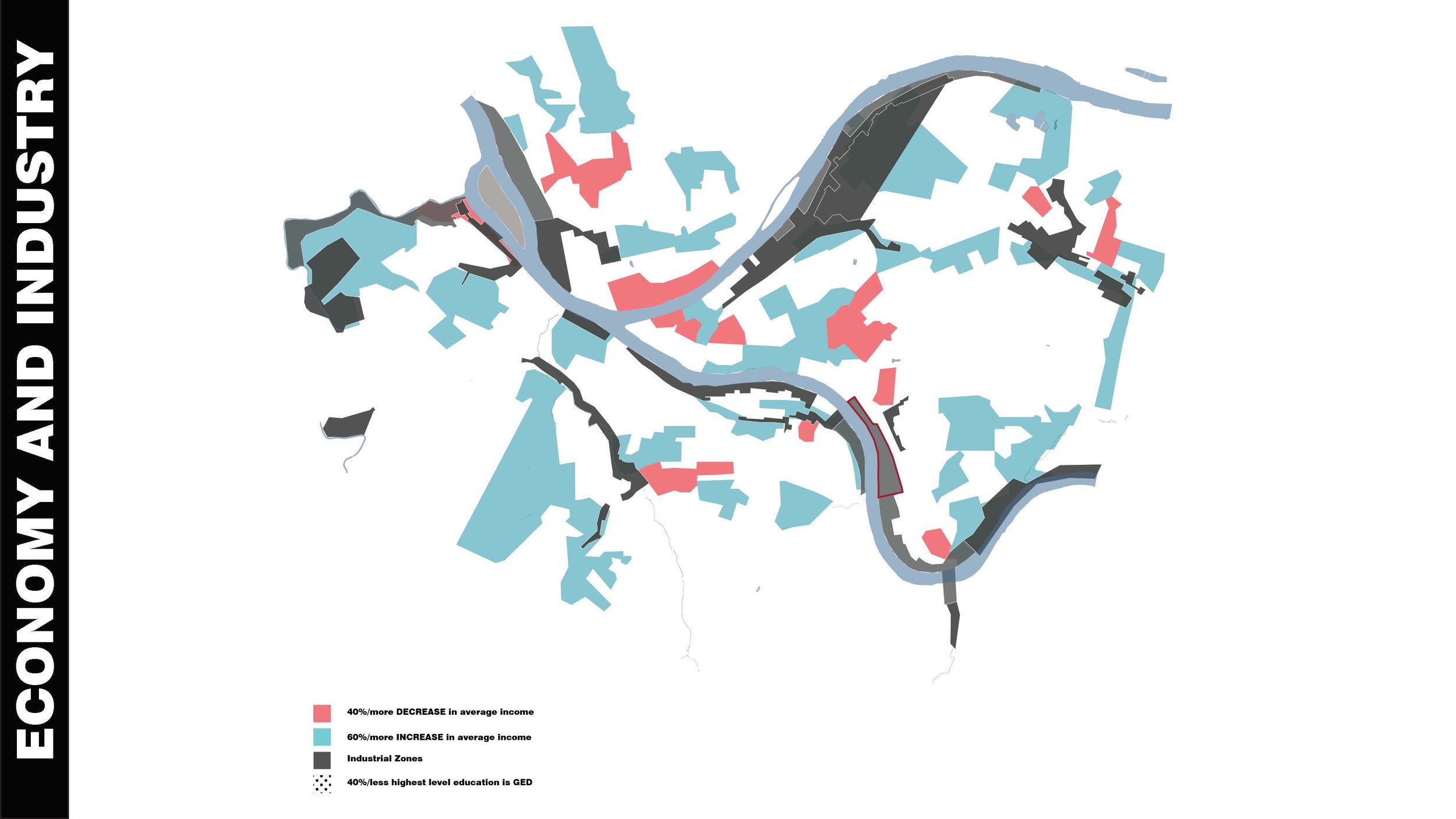

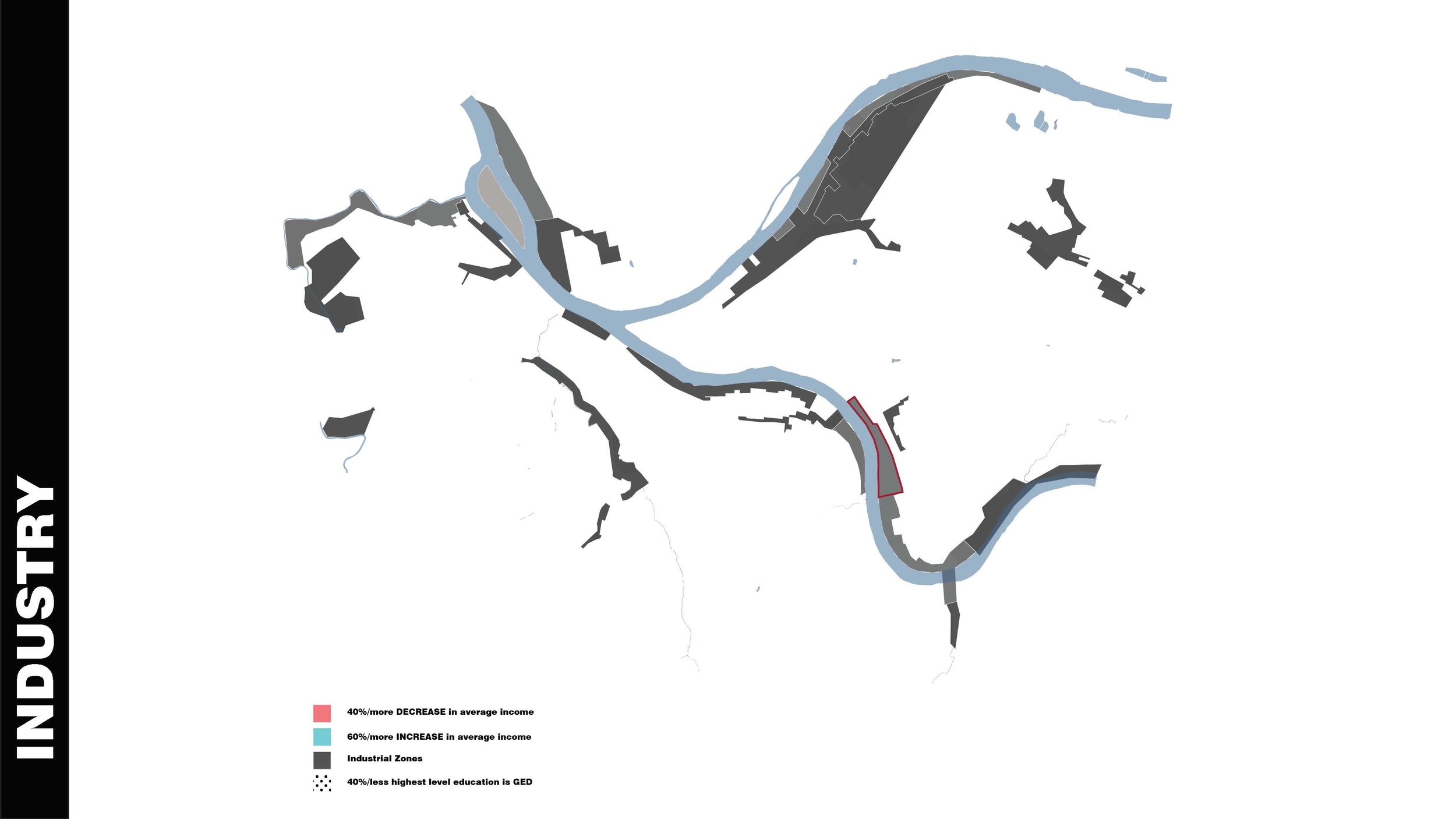

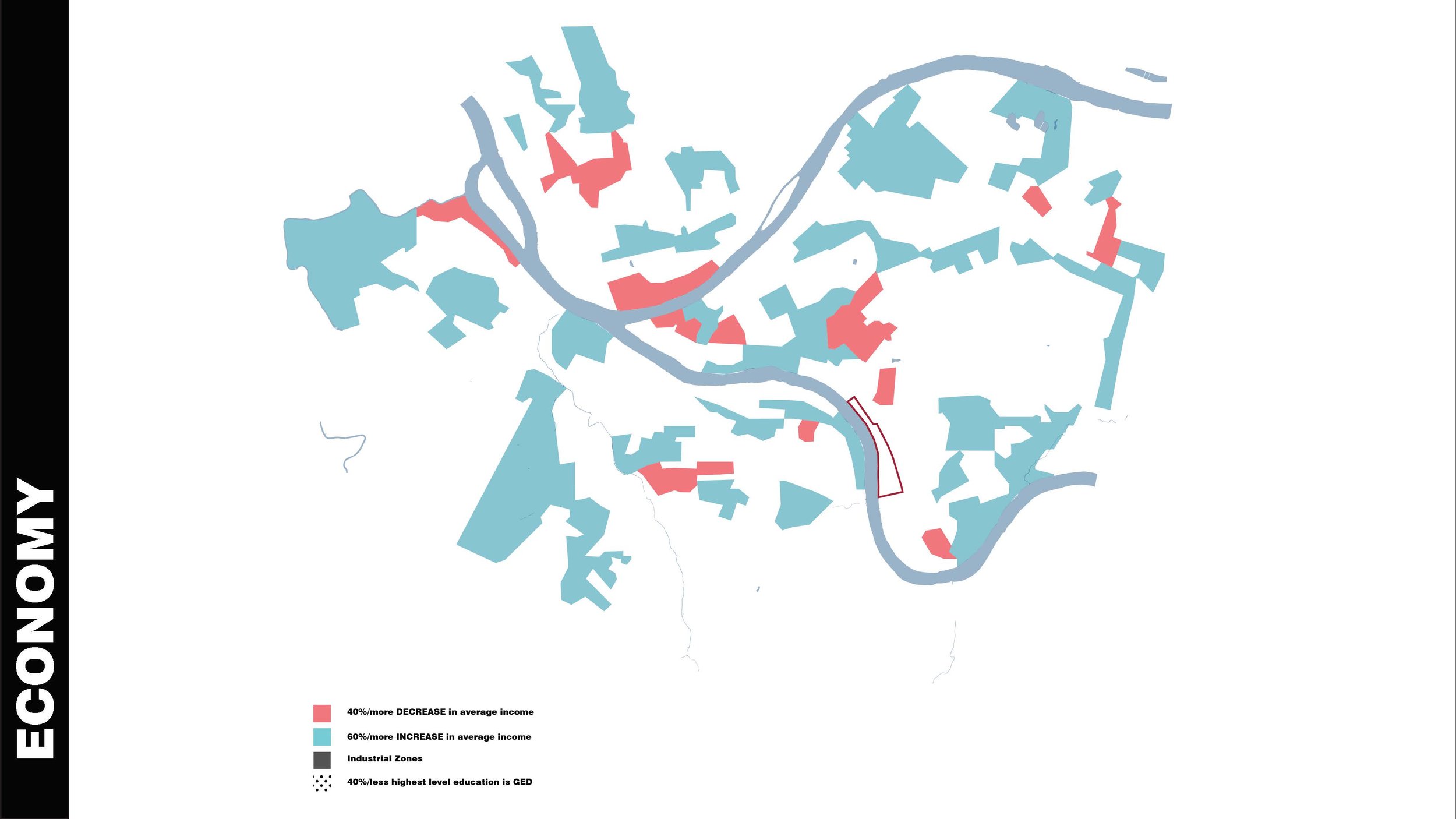

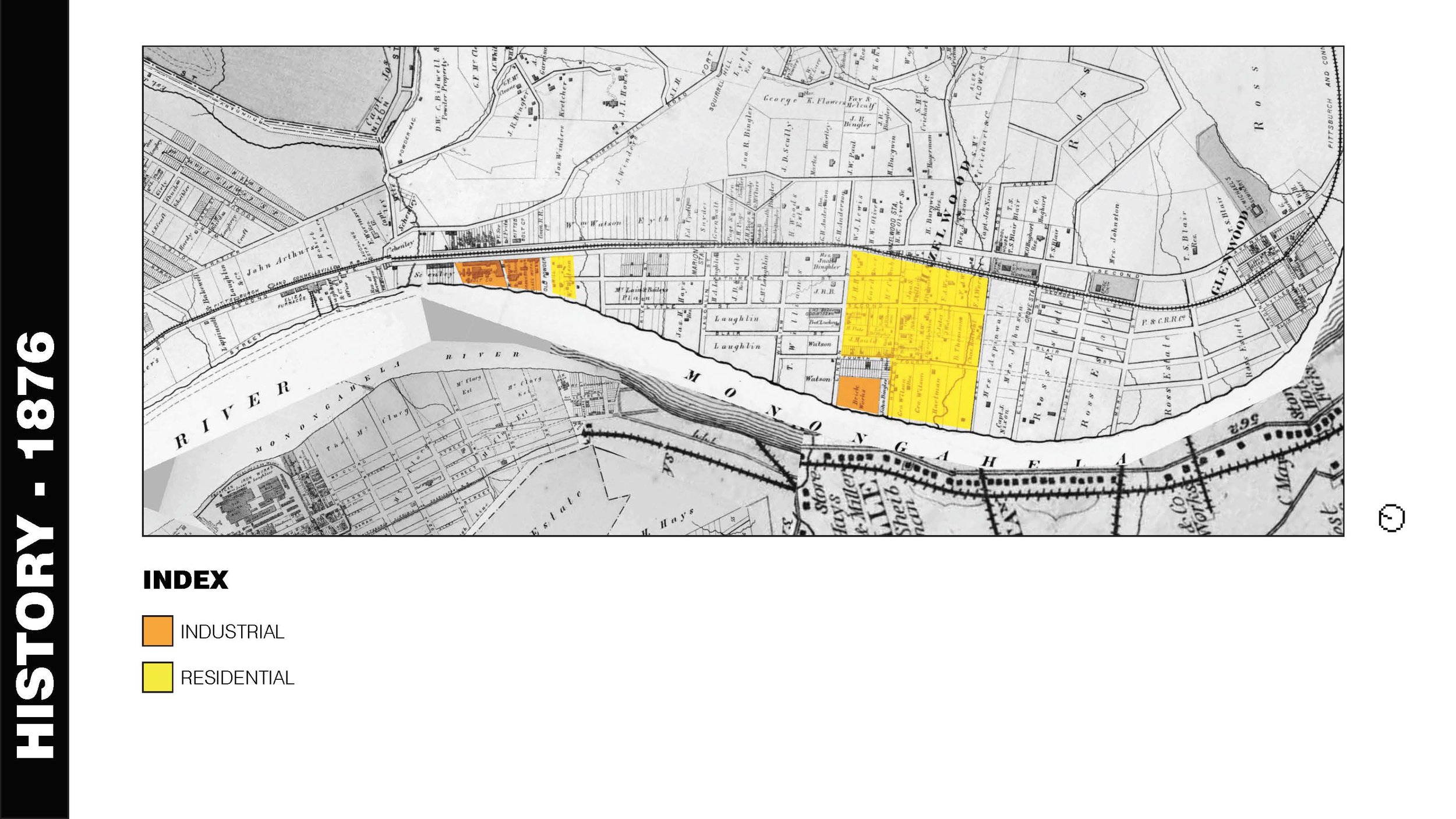

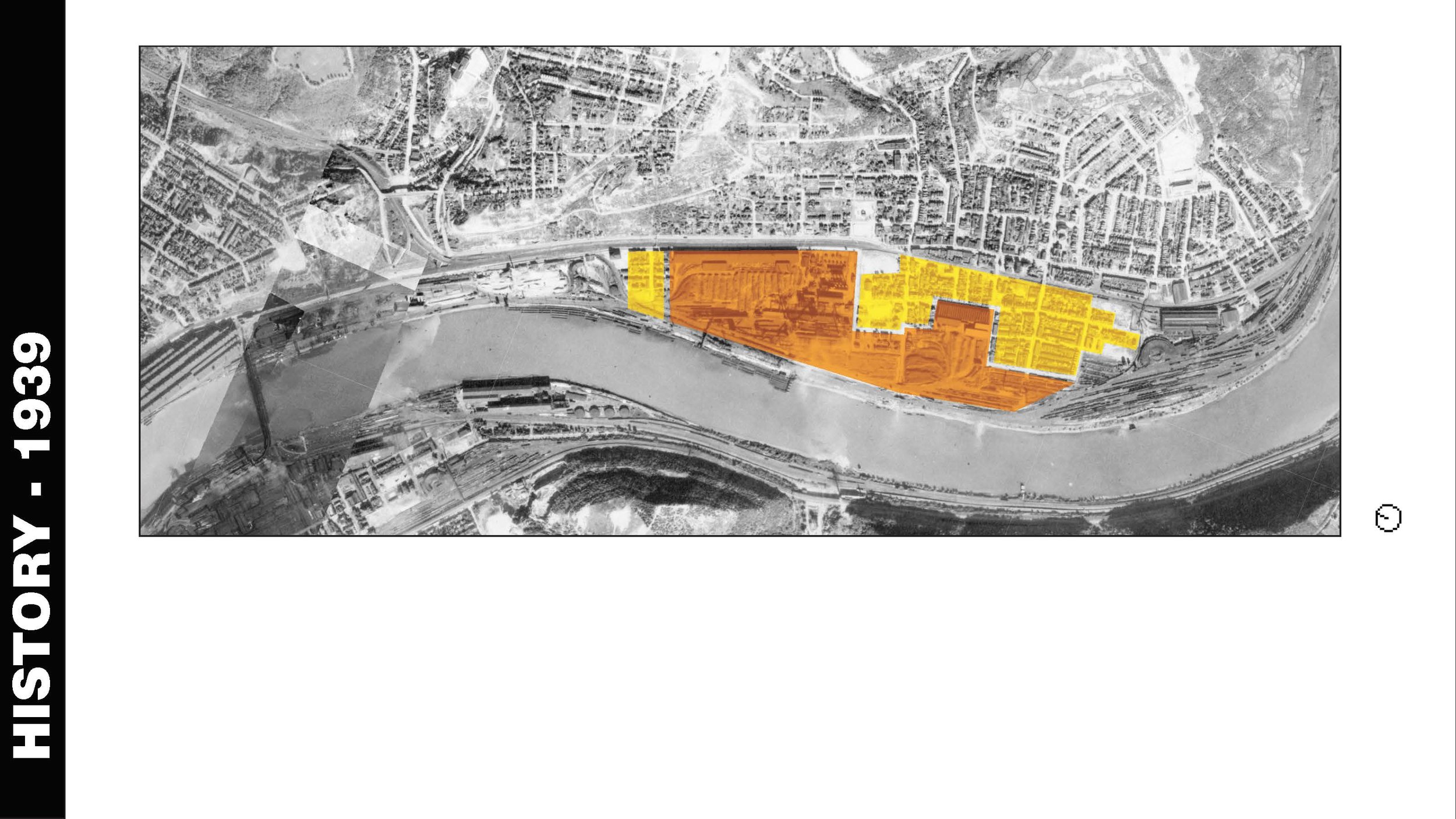

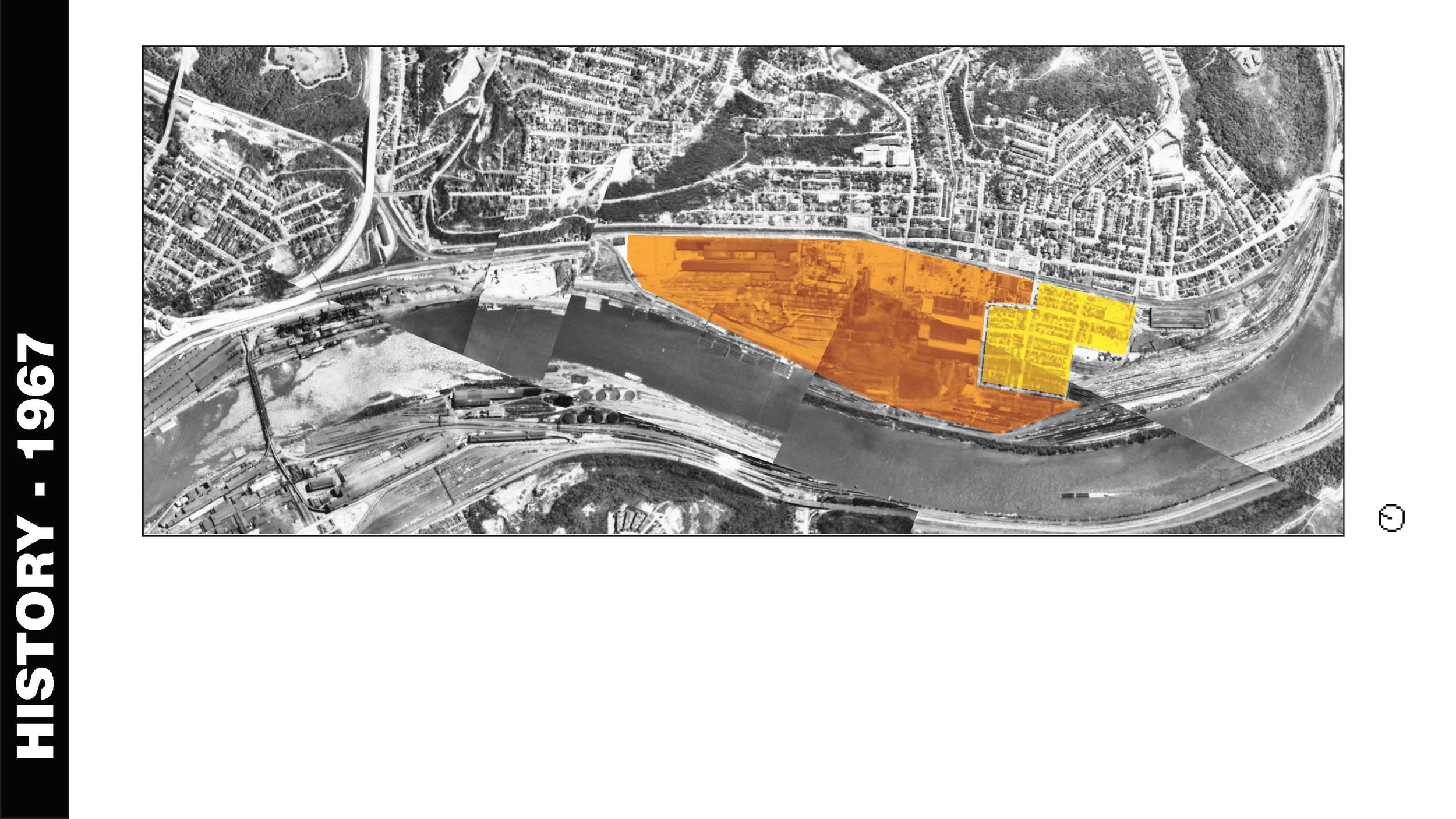

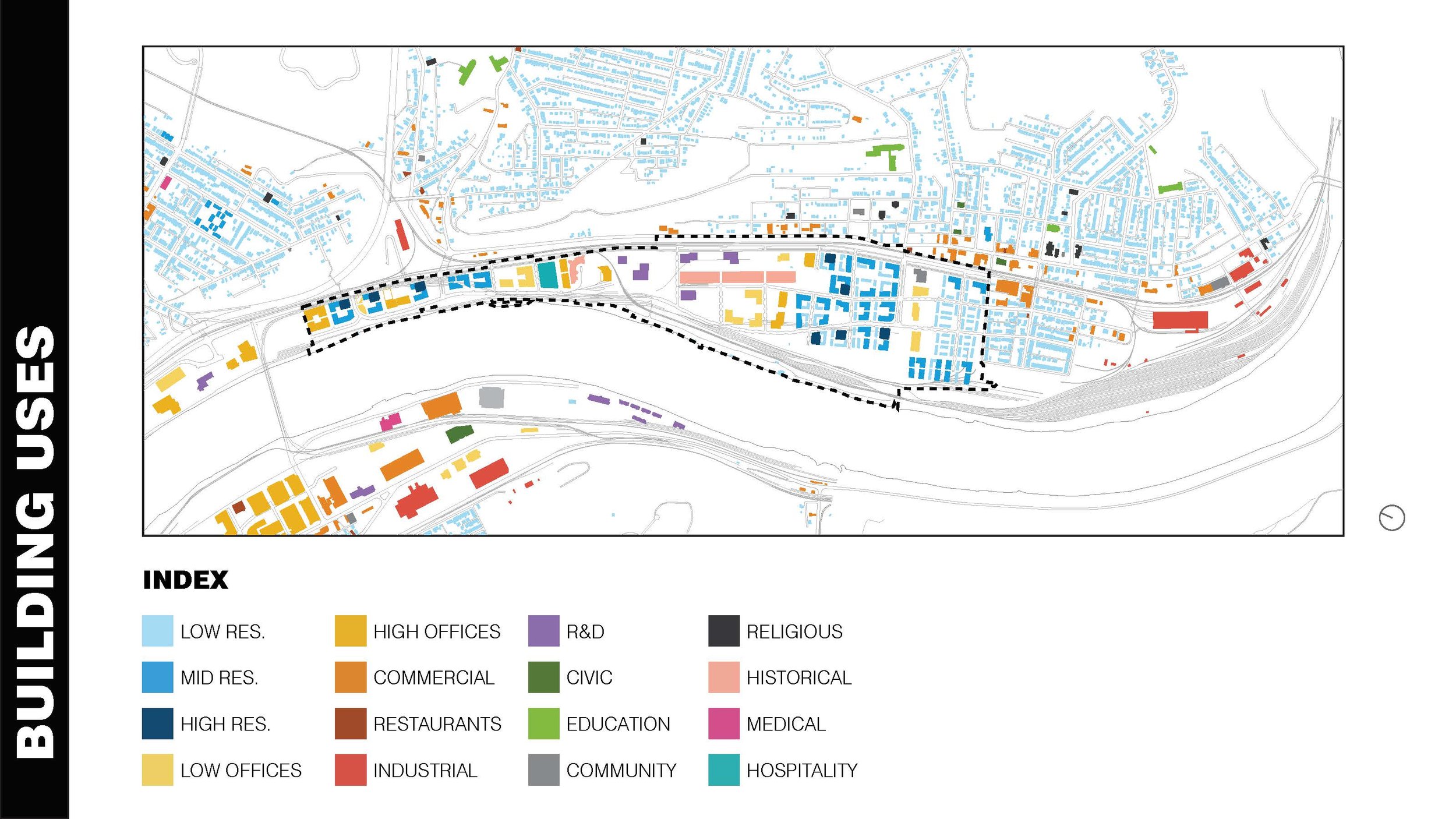

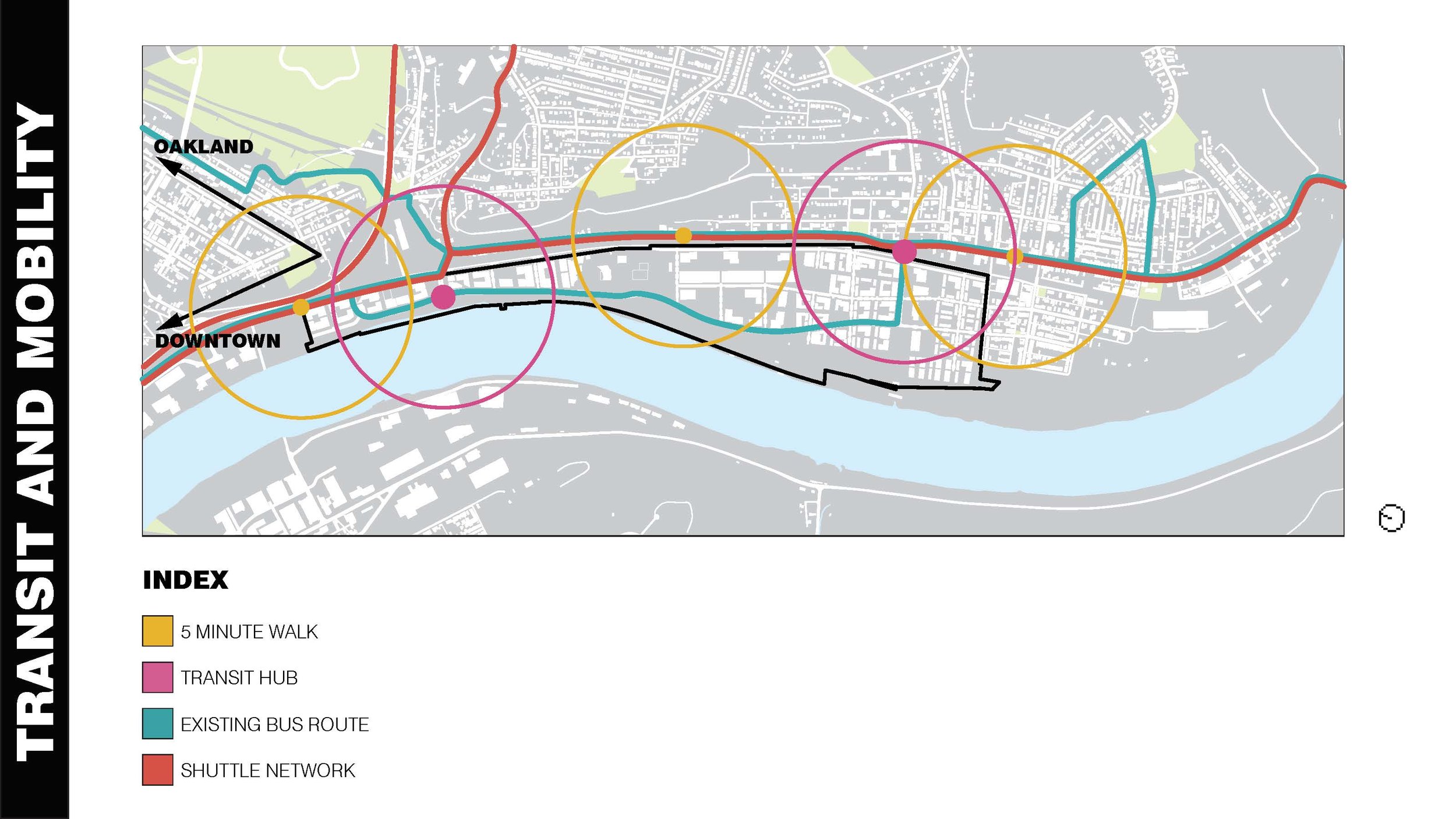

First, we studied the history of spatial dynamics between city and industry to understand how the emerging industries of 21st century would be contextualized within an urban setting.

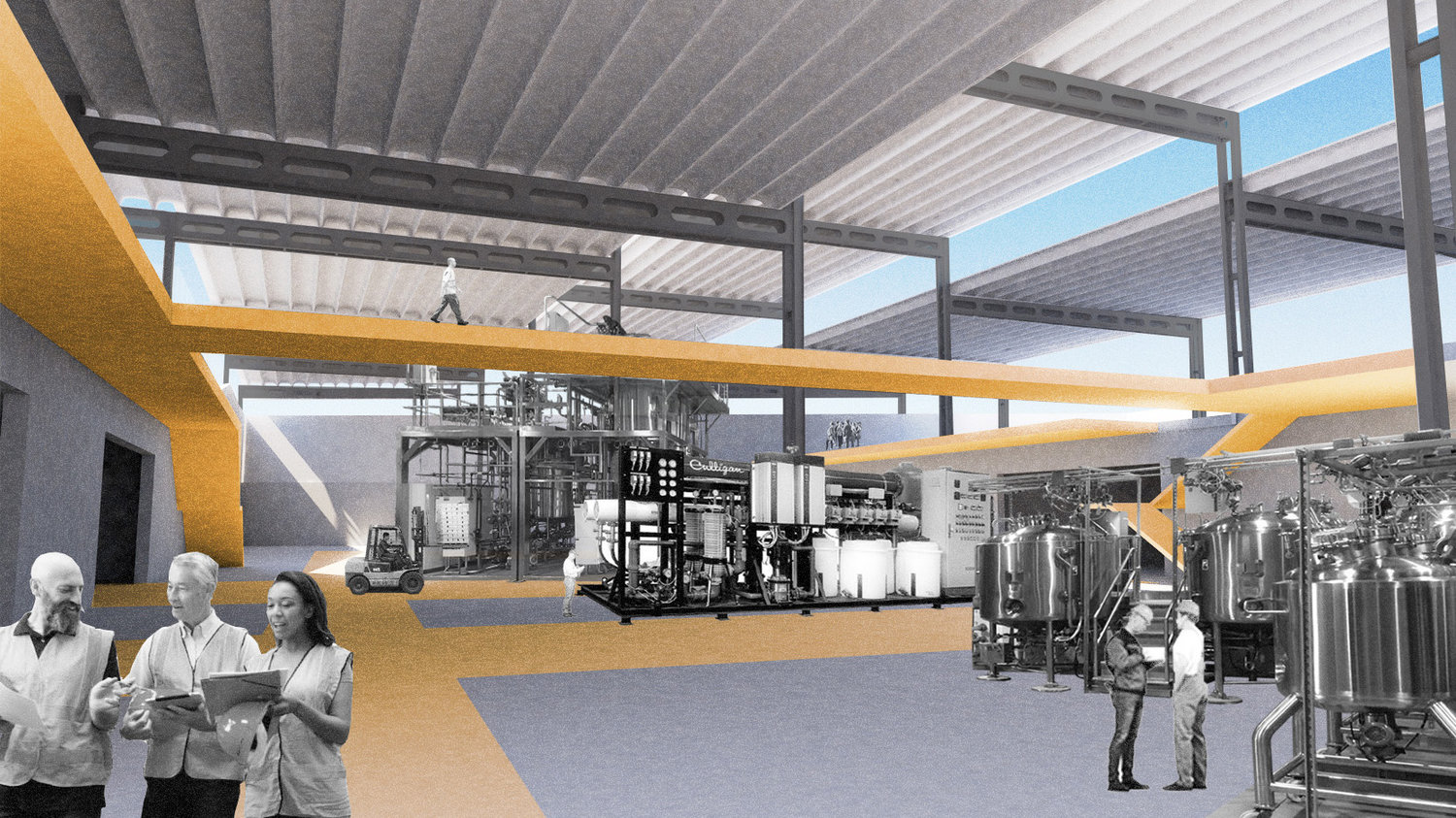

To address the economic and social feasibility, we visited multiple sites/factories that range from being historically influential to emerging. At these site visits, we interviewed workers and conducted collaborative exercises that helped us envision the ideal future of manufacturing in Hazelwood, Pittsburgh.

PHASE 2: CONCEPT EXPOSITION

After our interview with Robotany, a Pittsburgh-based start up that aims to rethink how we grow food with the aid of technology, the project concept was formed and verified by more research and interviews.

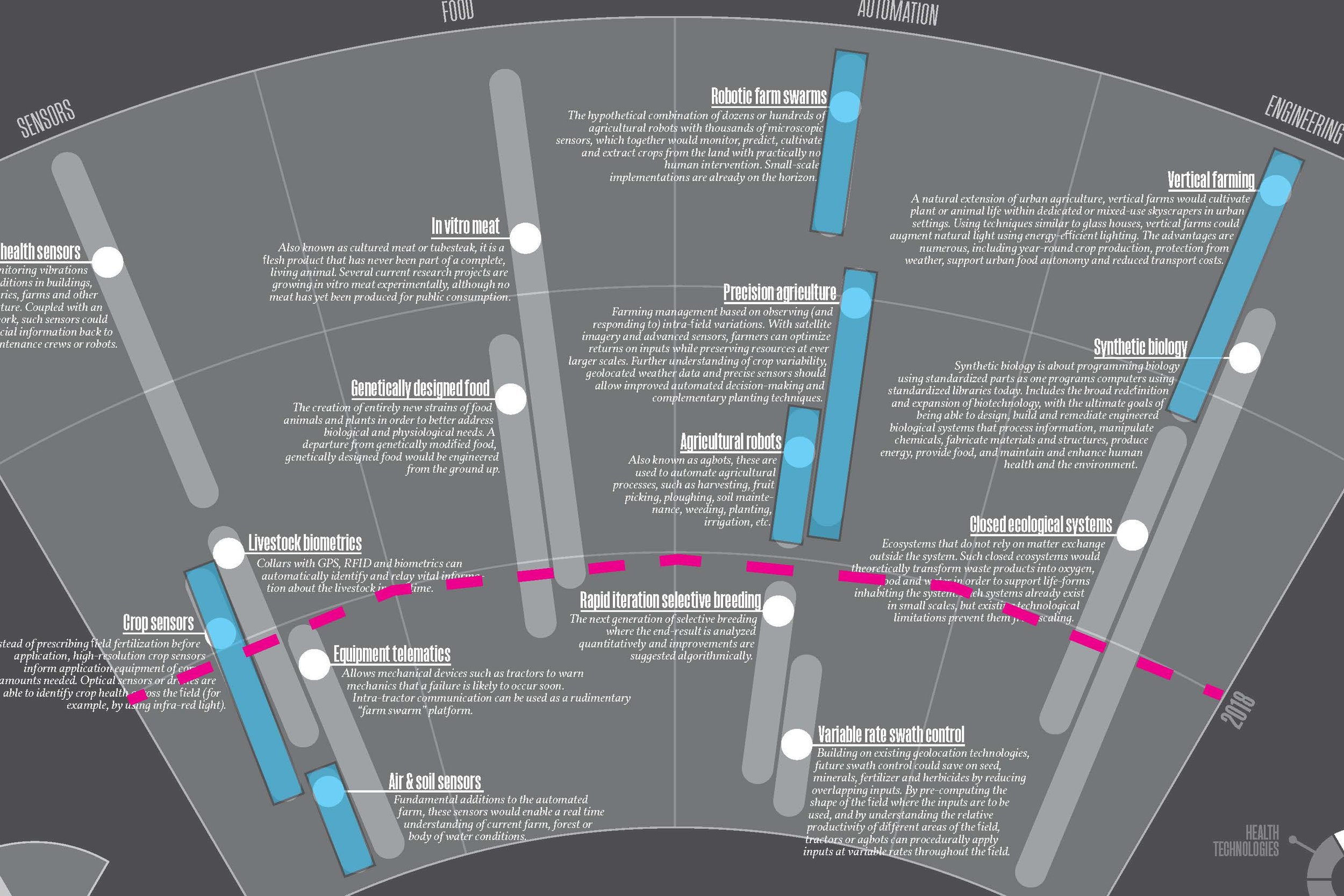

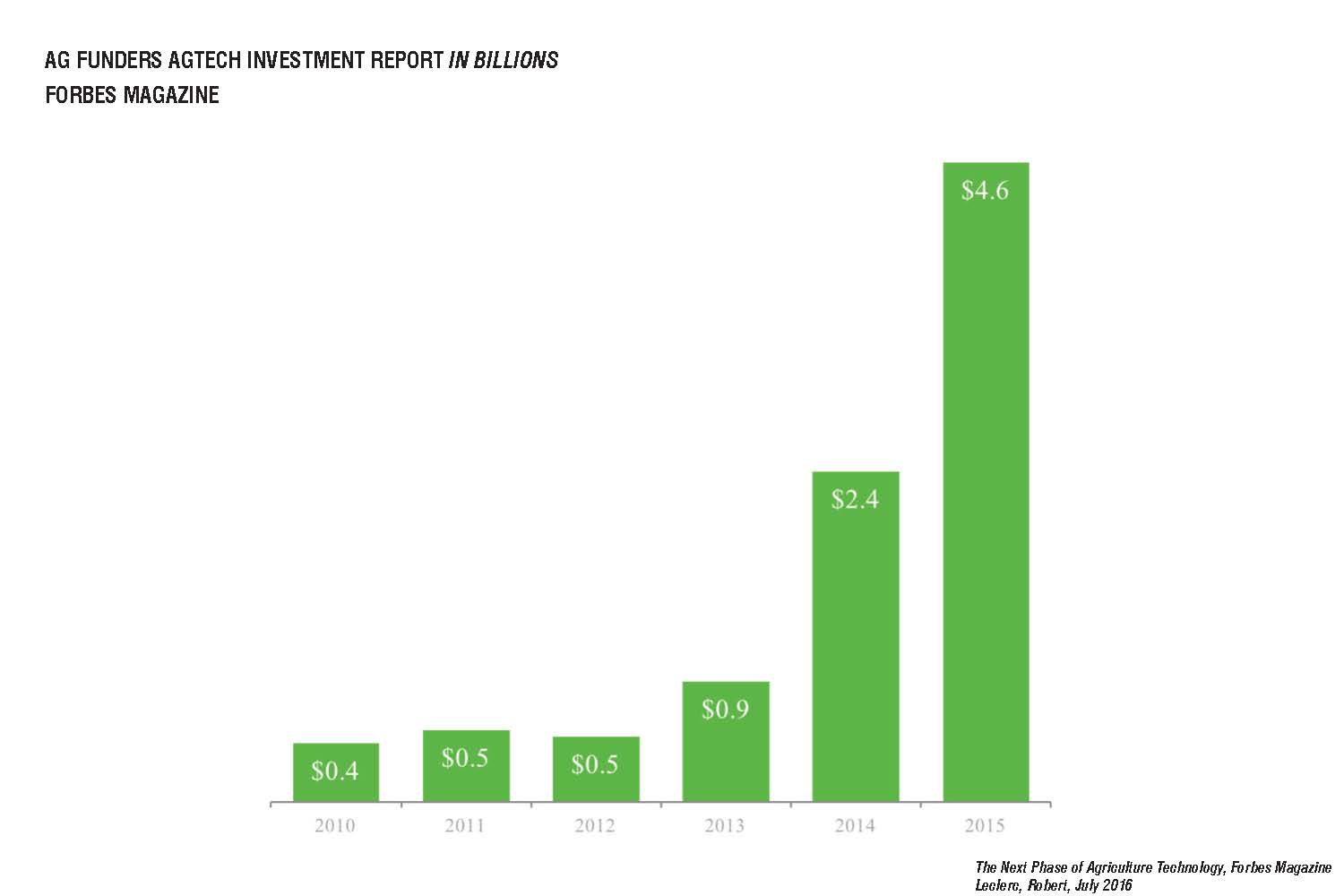

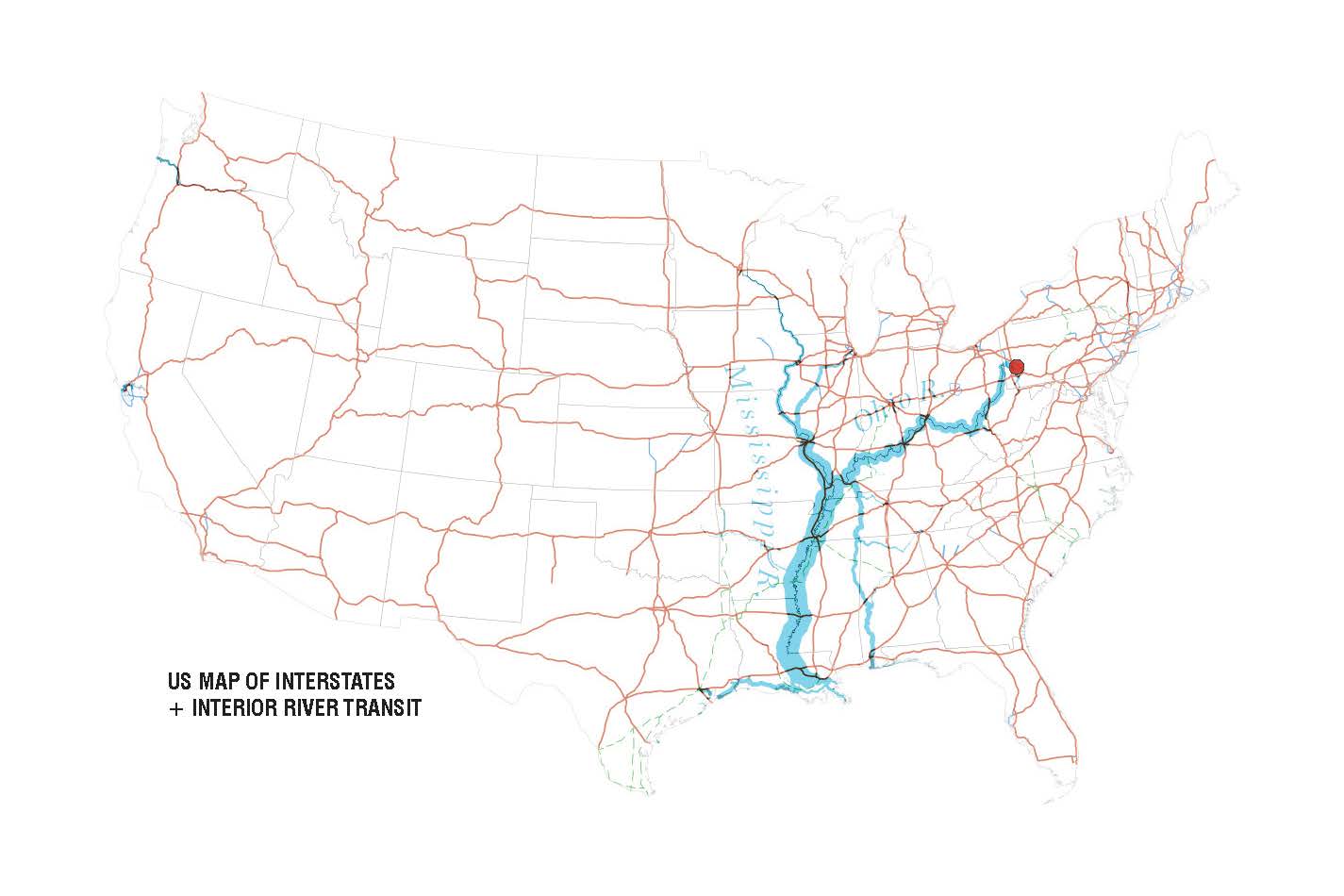

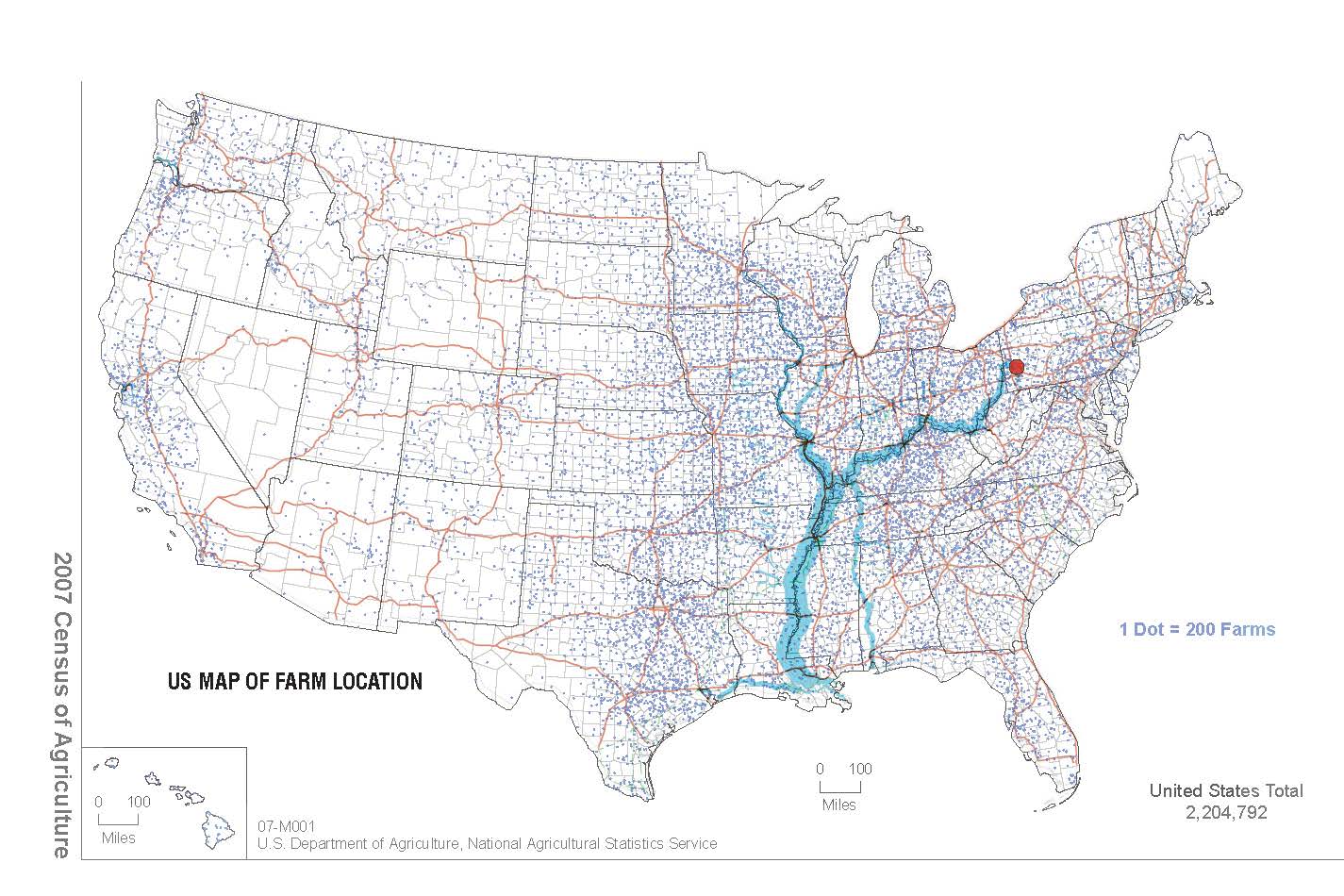

The following presentation was given to place AGTECH initiatives as part of emerging technologies within a contemporary timeline, and to establish when these tools will reach market viability. Pittsburgh is an ideal city to situate a vertically integrated Tech & Produce facility, given its inefficiency with growing and transporting food from remote regions.

PHASE 3: PROGRAMMING

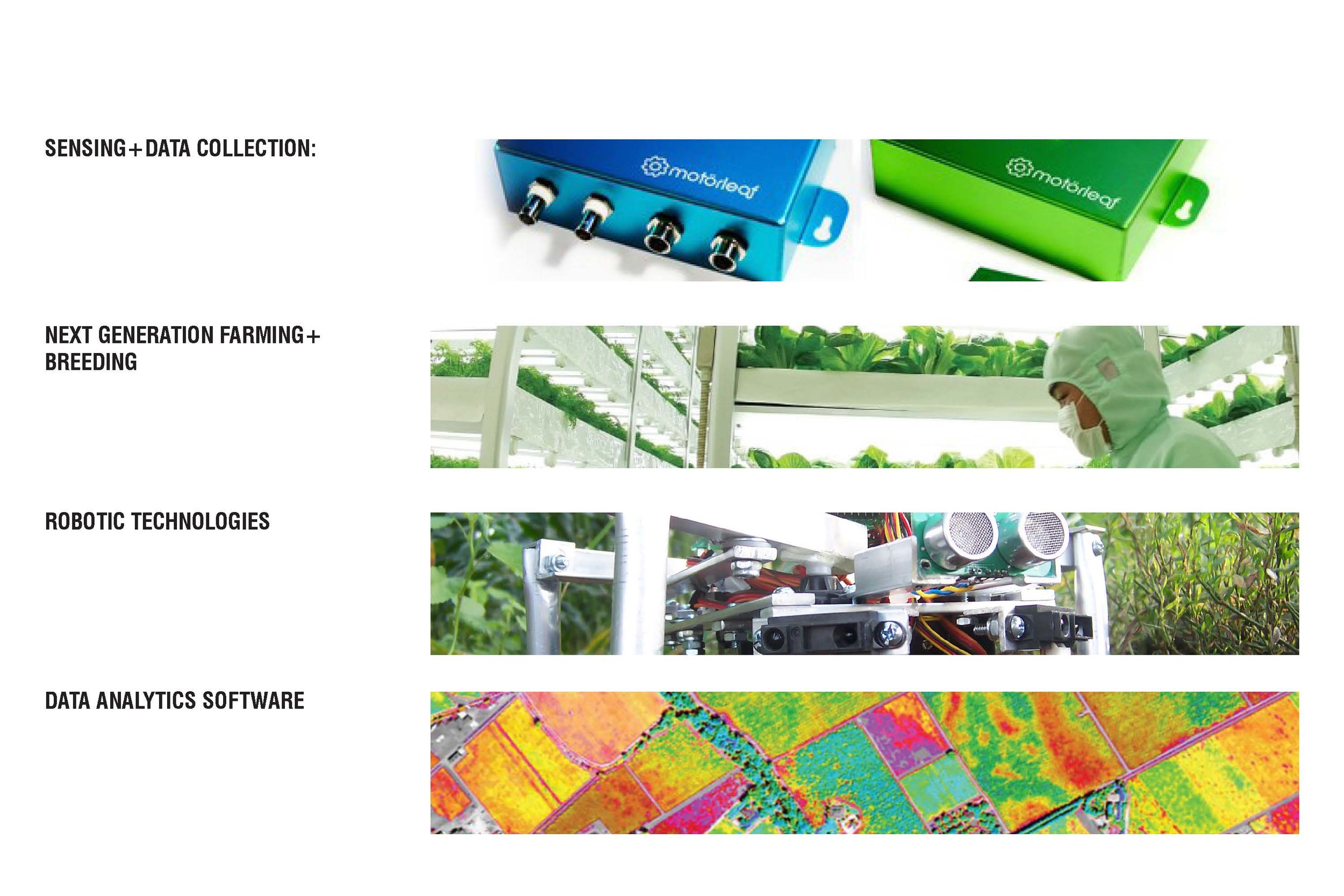

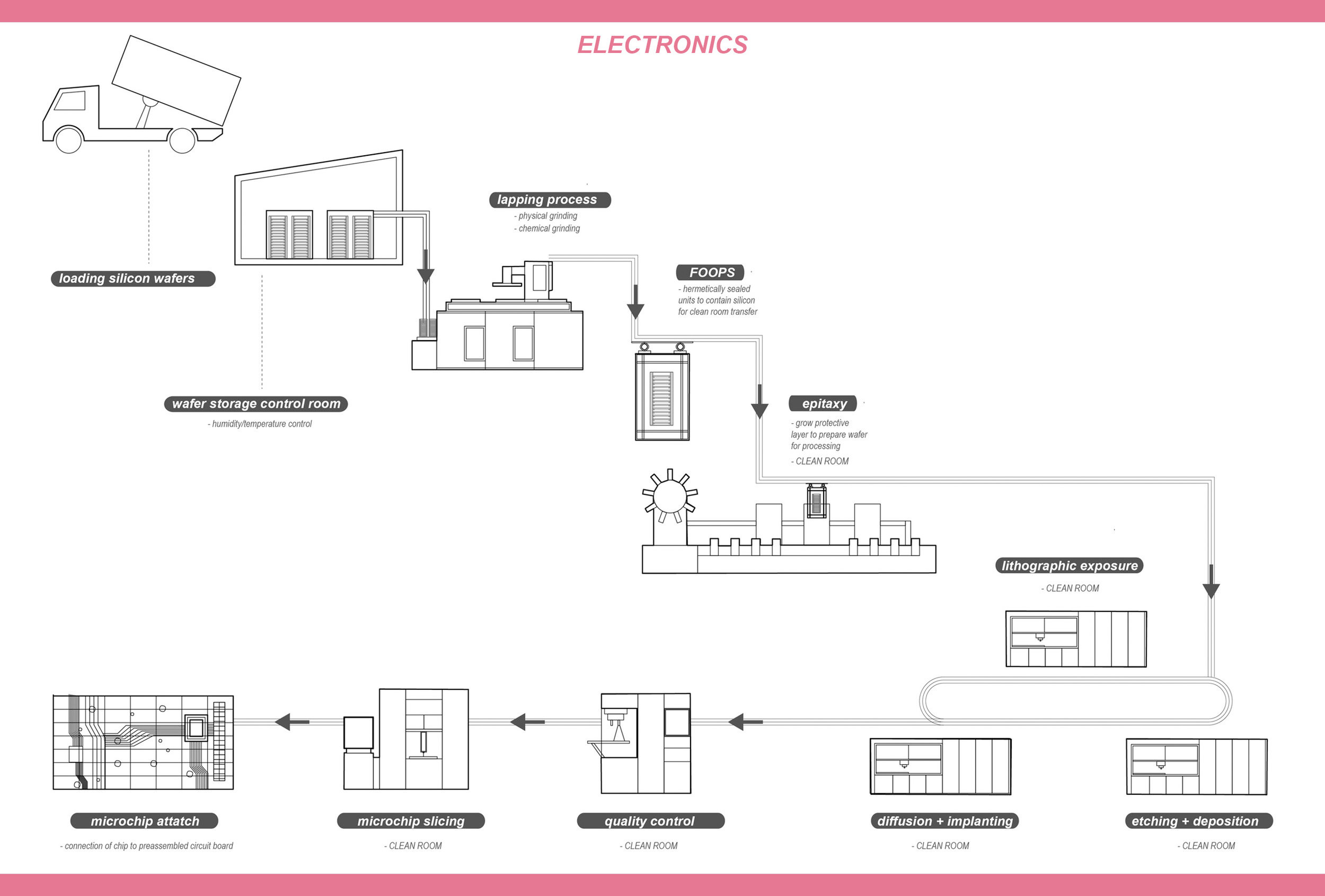

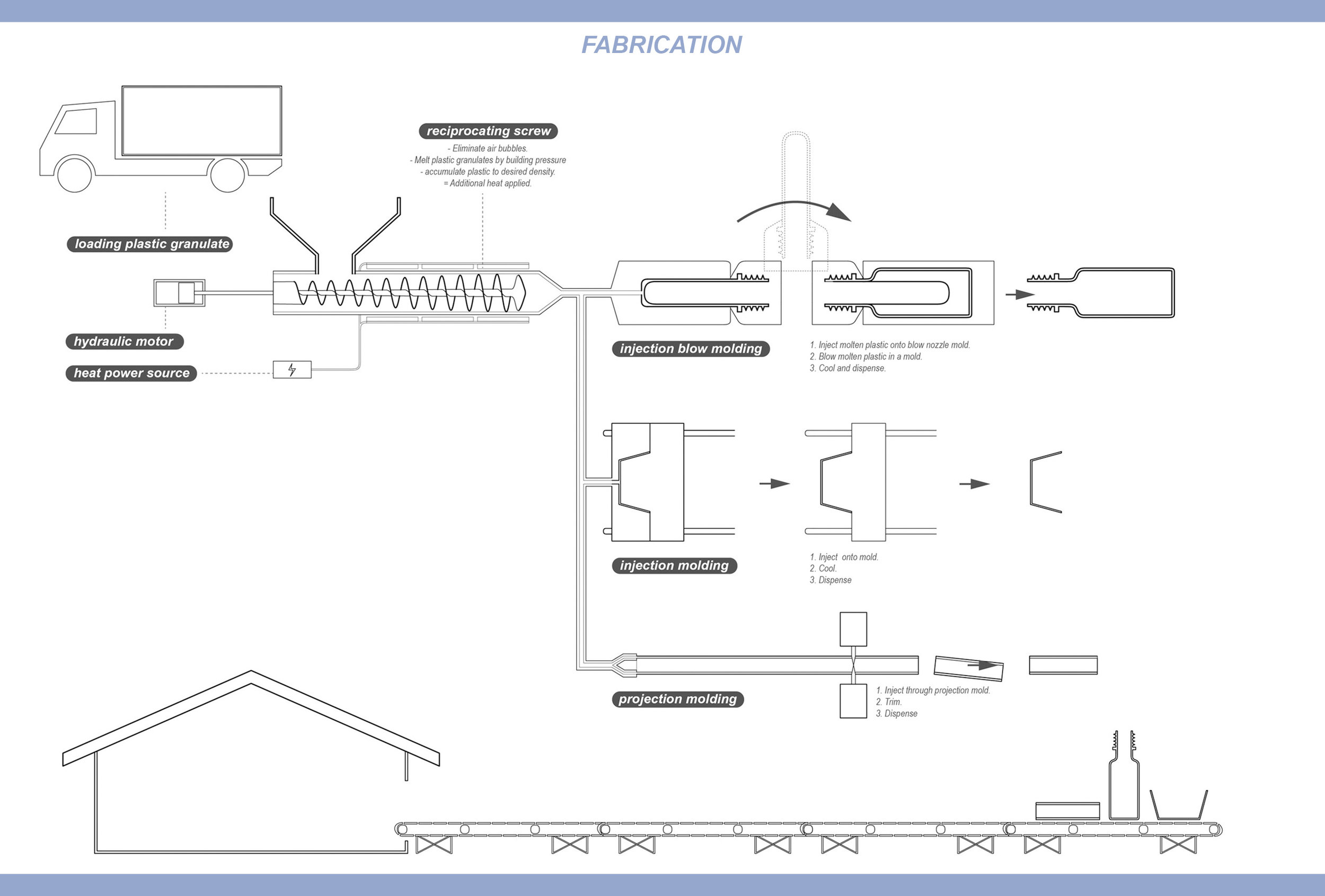

In defining our project as a part of AGTECH sector, we mapped underlying elements of program, understanding the types of products to be produce. Through this process we identified key components to our manufacturing design.

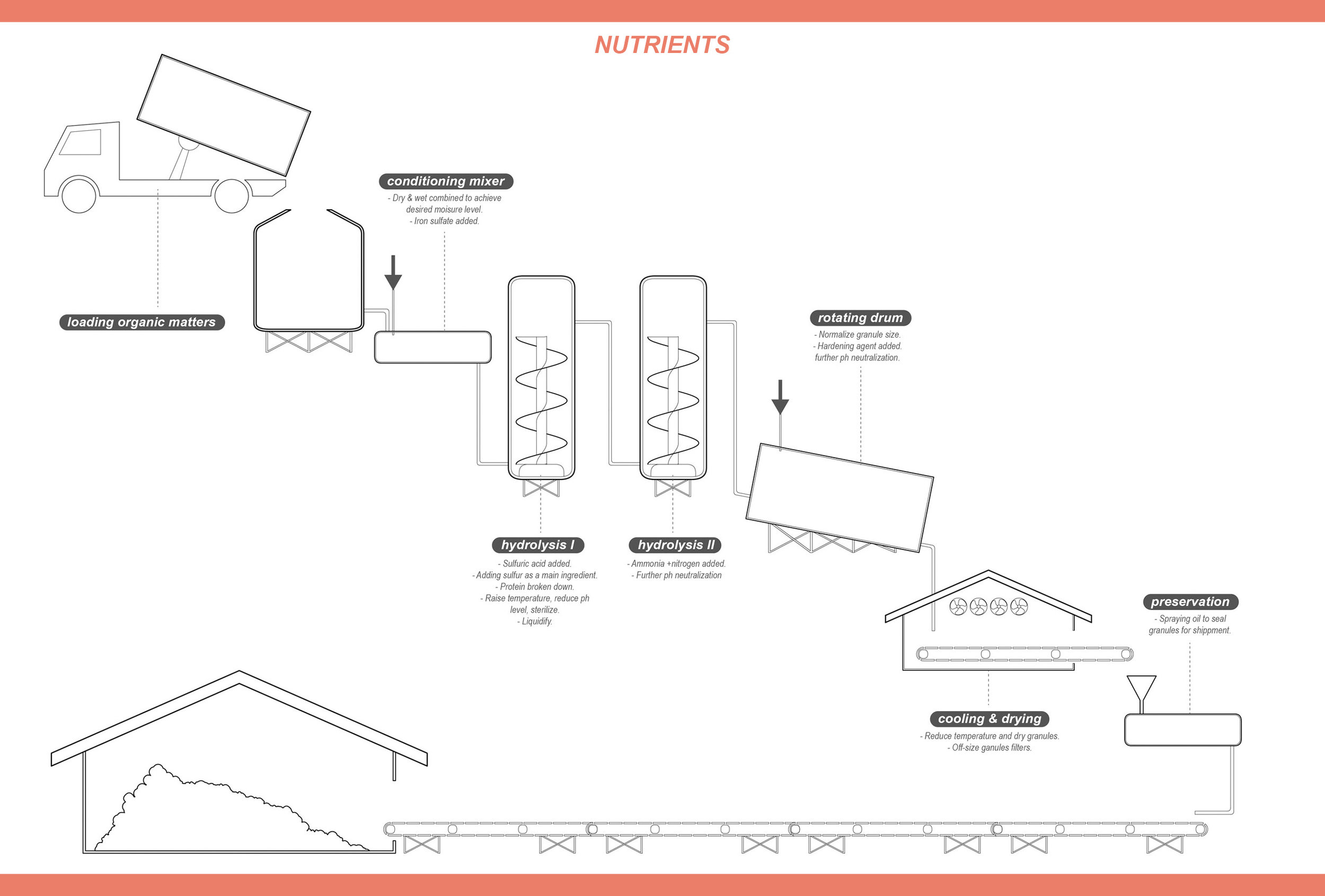

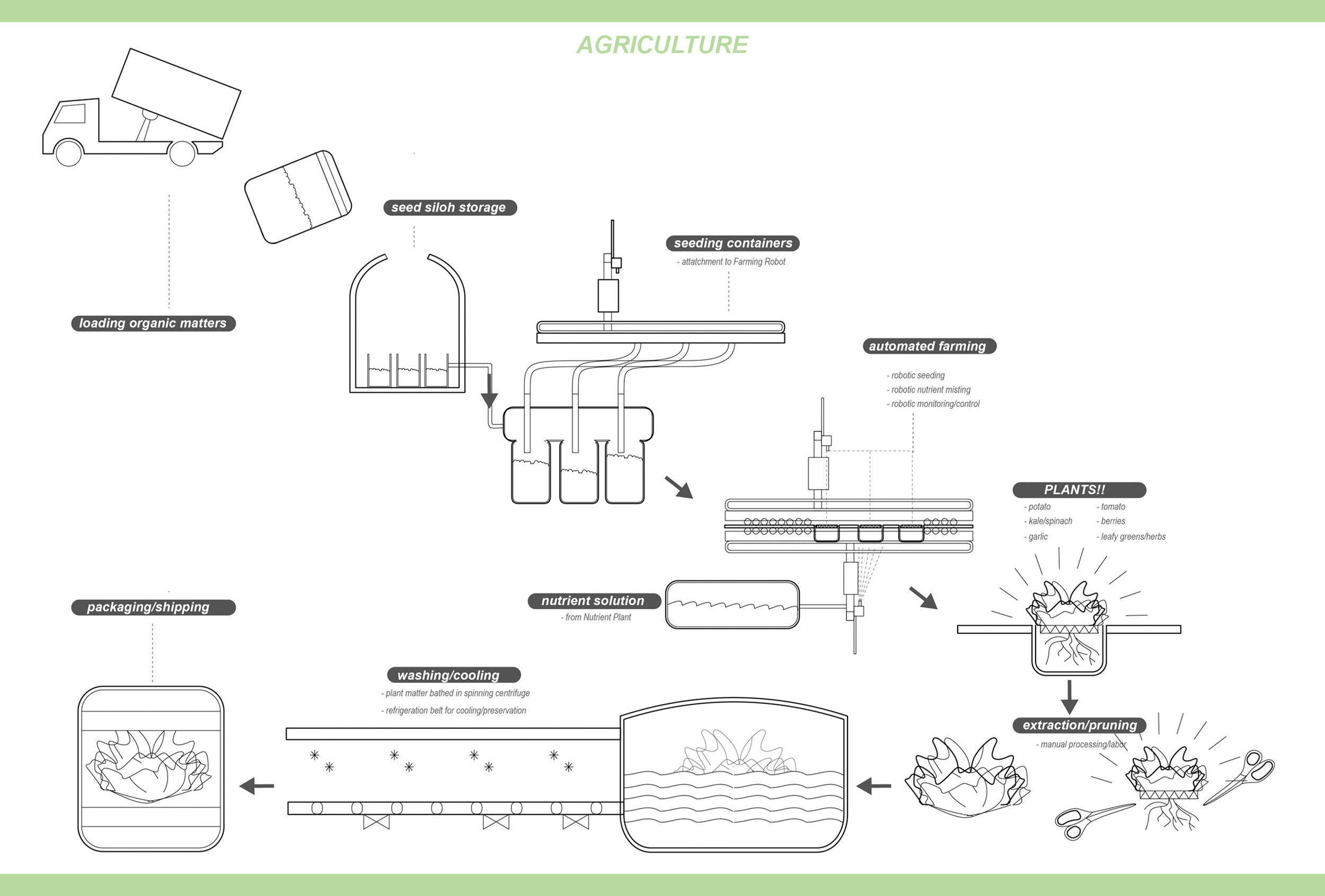

Firstly, a manufacturing and fabrication facility for the creation of tools, robotic technologies and made to order farm shells. Secondly, a fertilizer processing plant, for the creation of plant specific nutrient solutions that are intended to be sold as a commercially viable. Thirdly, an office and laboratory spaces, where new analytics software and electronic hardware are tested. Lastly, vertical urban agricultural facilities that grow and showcase the produce.

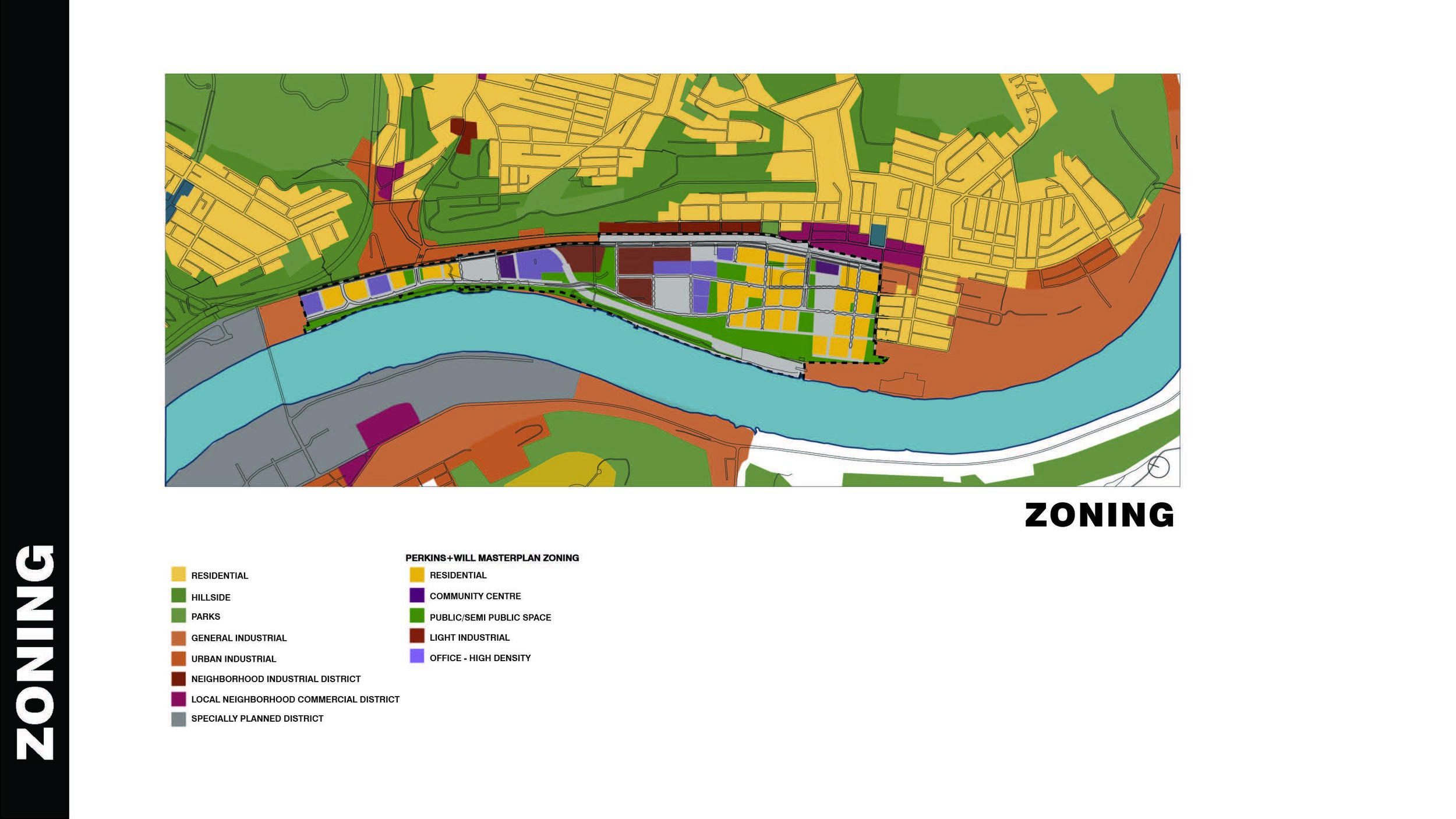

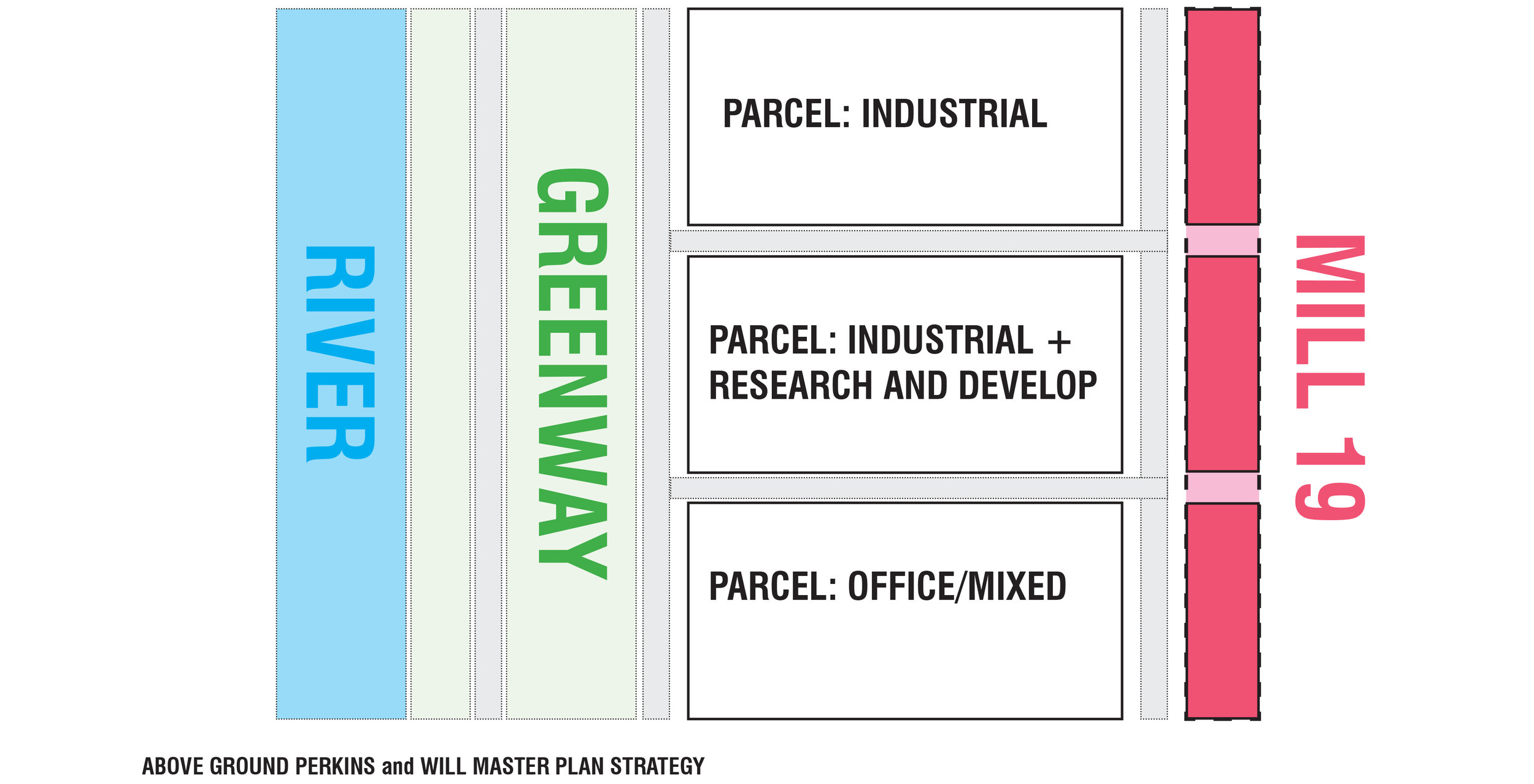

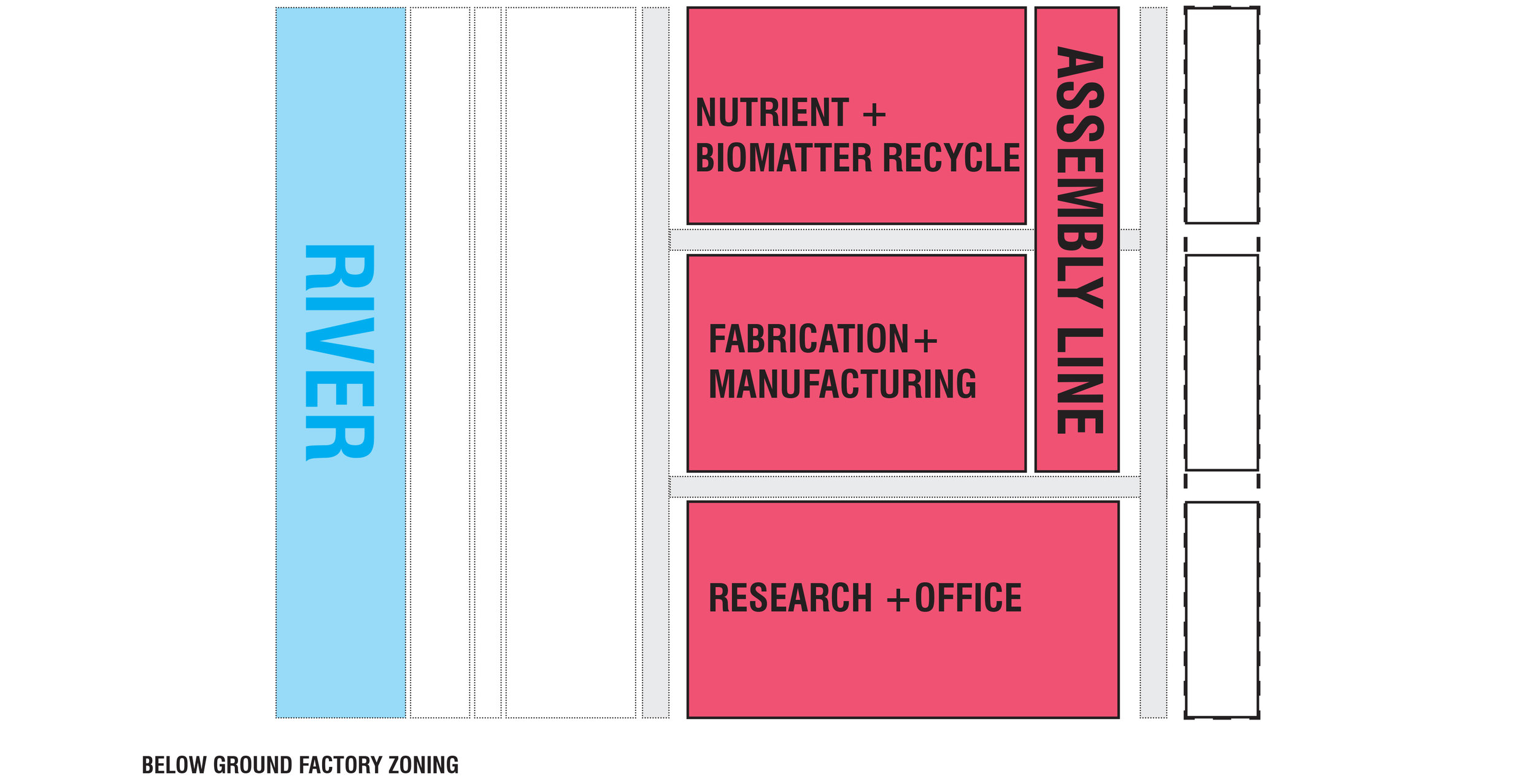

PHASE 4: SITE PLANNING STRATEGY

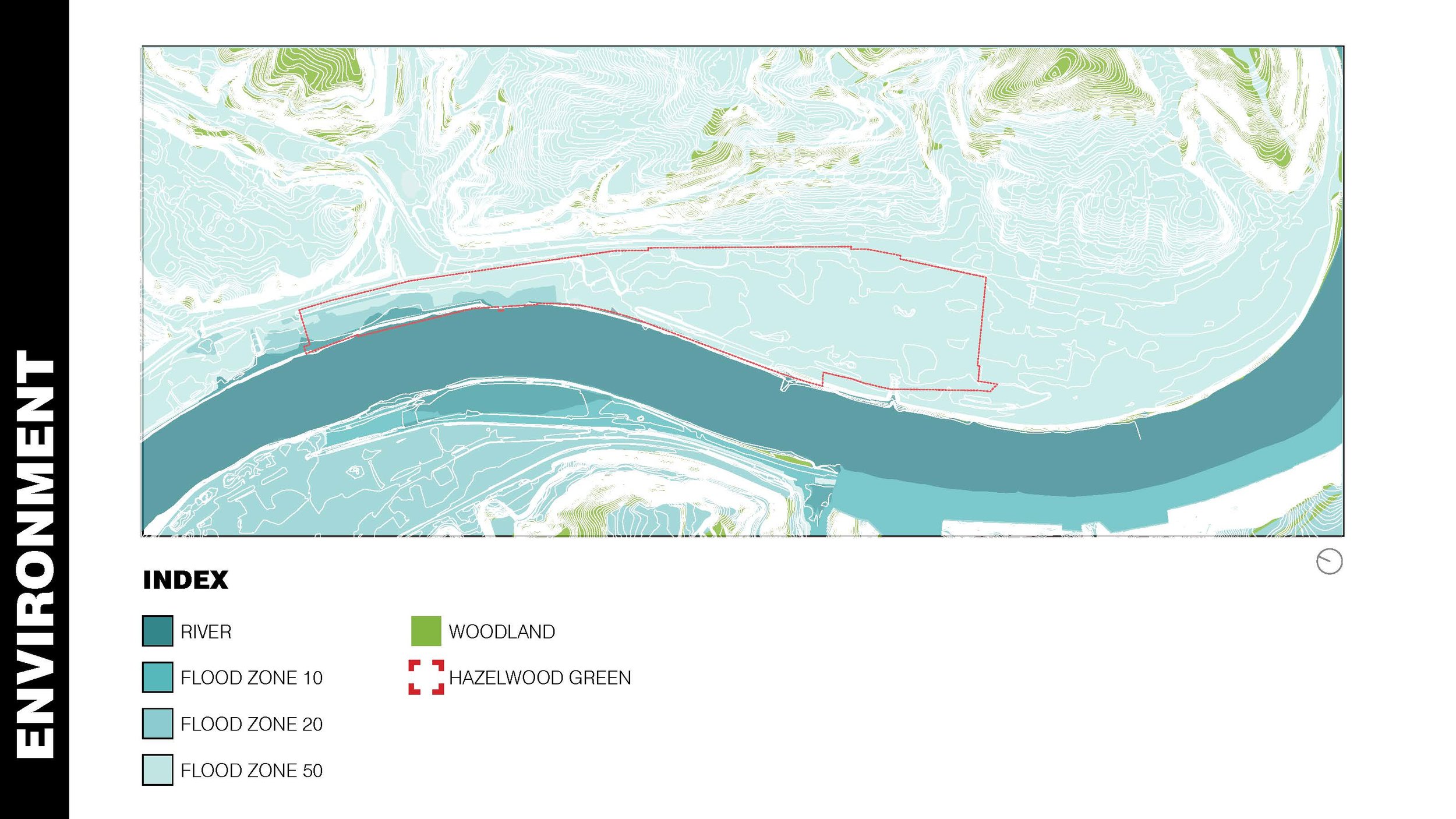

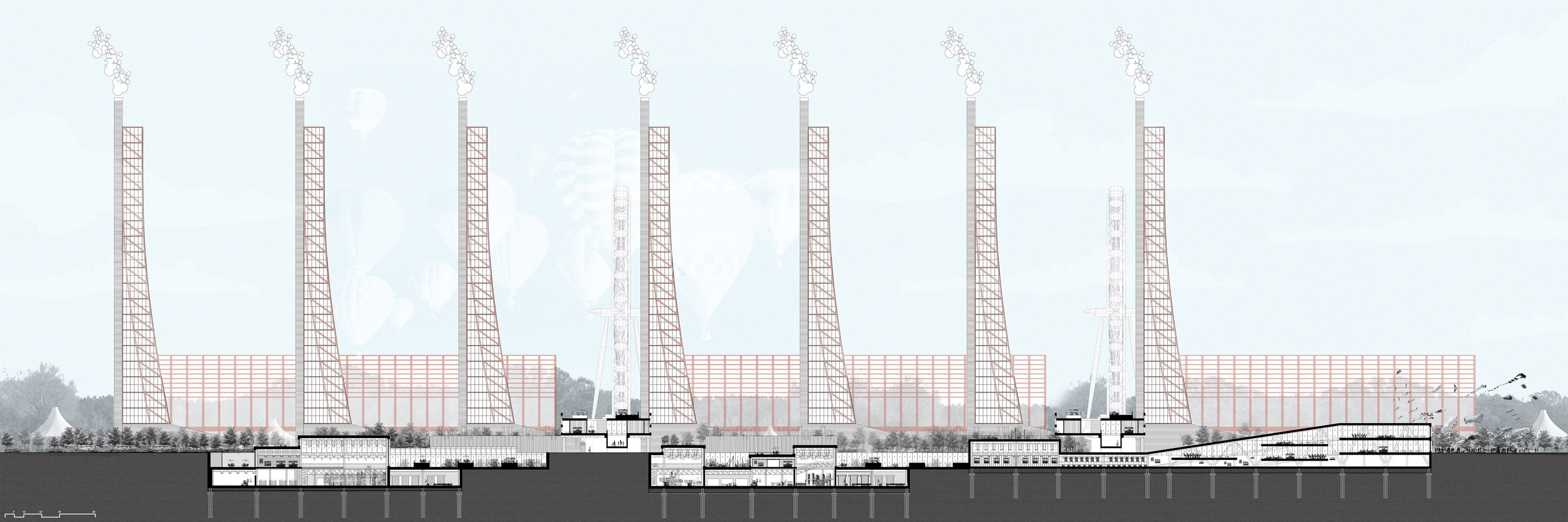

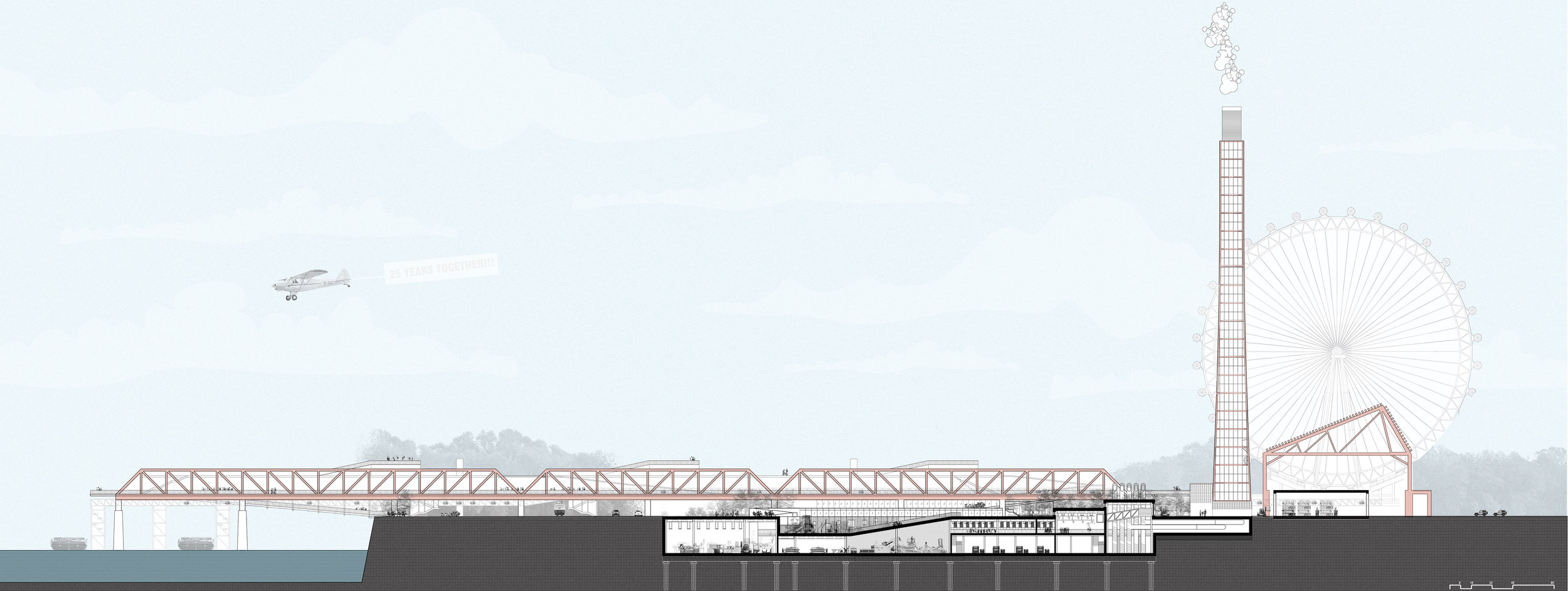

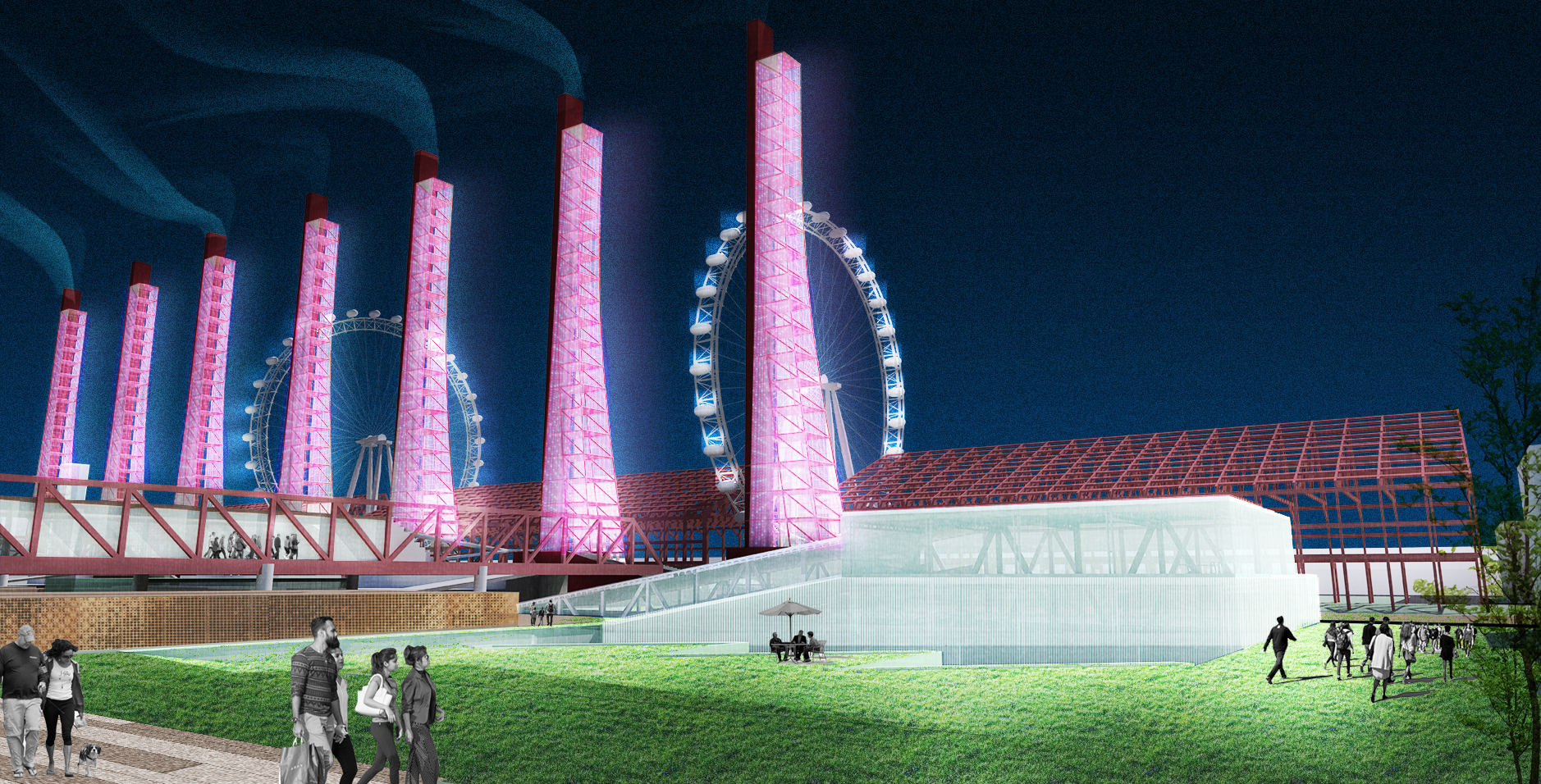

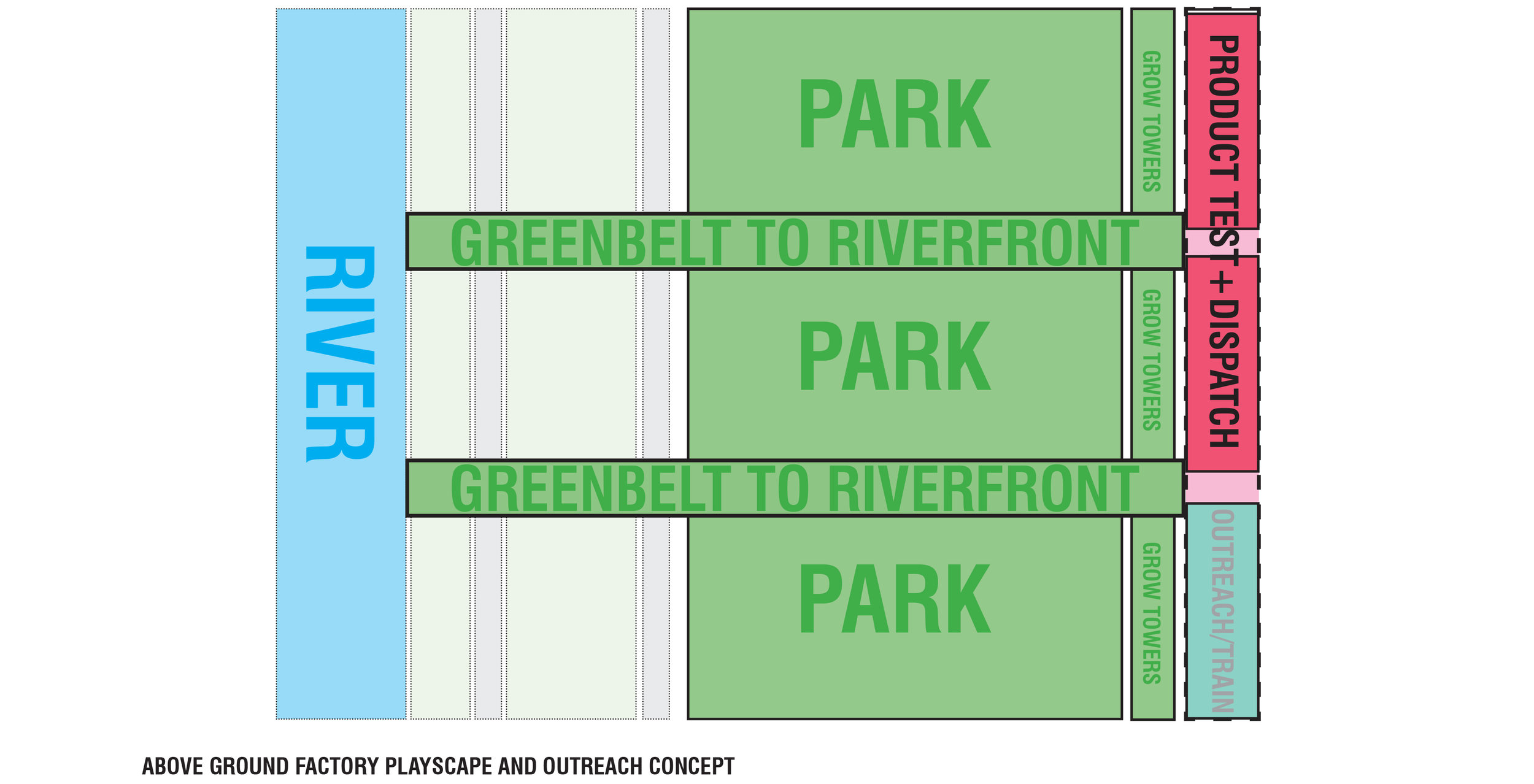

Given the three parcel allotment, we choose to compartmentalize our facility into three main zones under the ground, reserving the northern most parcels for production and the southern most for office and research, as reflected in the existing plan. These zones become connected through an assembly line that connects the fabrication and nutrient facility together, to then ship products to dispatch and test in the Mill Building itself. Thus above ground, all of the space that could have been occupied with the facility become open available public park, with transverse seams called the "Green Belts" serving to connect the public with the Riverfront, which bridges over the site in order to allow enough clear height to pass the active rail line separating the park from the riverfront.

Hazelwood: Site

plans

From left to right: Basement, Ground, Second Level

PHASE 5: ARCHITECTURE

The final solution involved utilizing the roofscape of the factory below to describe partially elevated occupiable public decks. Ferris wheels serve to lift the public to the skydecks in 2 of the vertical towers, and also transport materials for dispatch along the elevated greenbelts to the riverfront for barge transit. The factory below gains access to the landscape through sculpted terraces which reveal the western faces of most of the worker amenity spaces, thus creating a relationship between the more public-ally accessible parts of the complex and the workers themselves, who by happenstance may meet on these terraces. Slight alteration in material on the groundscape indicated area for events, main circulation or permanent stations of activity such as food trucks and stages, while the remaining greenscape retains room for sports amenities such as tennis and basketball courts.

Detailed Axons

“Fertilize”

“Make”