CONCRETE PRINTING

2017, supervised by Joshua Bard, Dana Cupkova,

in collaboration with Cy Kim, Dan Cascaval, Manuel Rodriguez

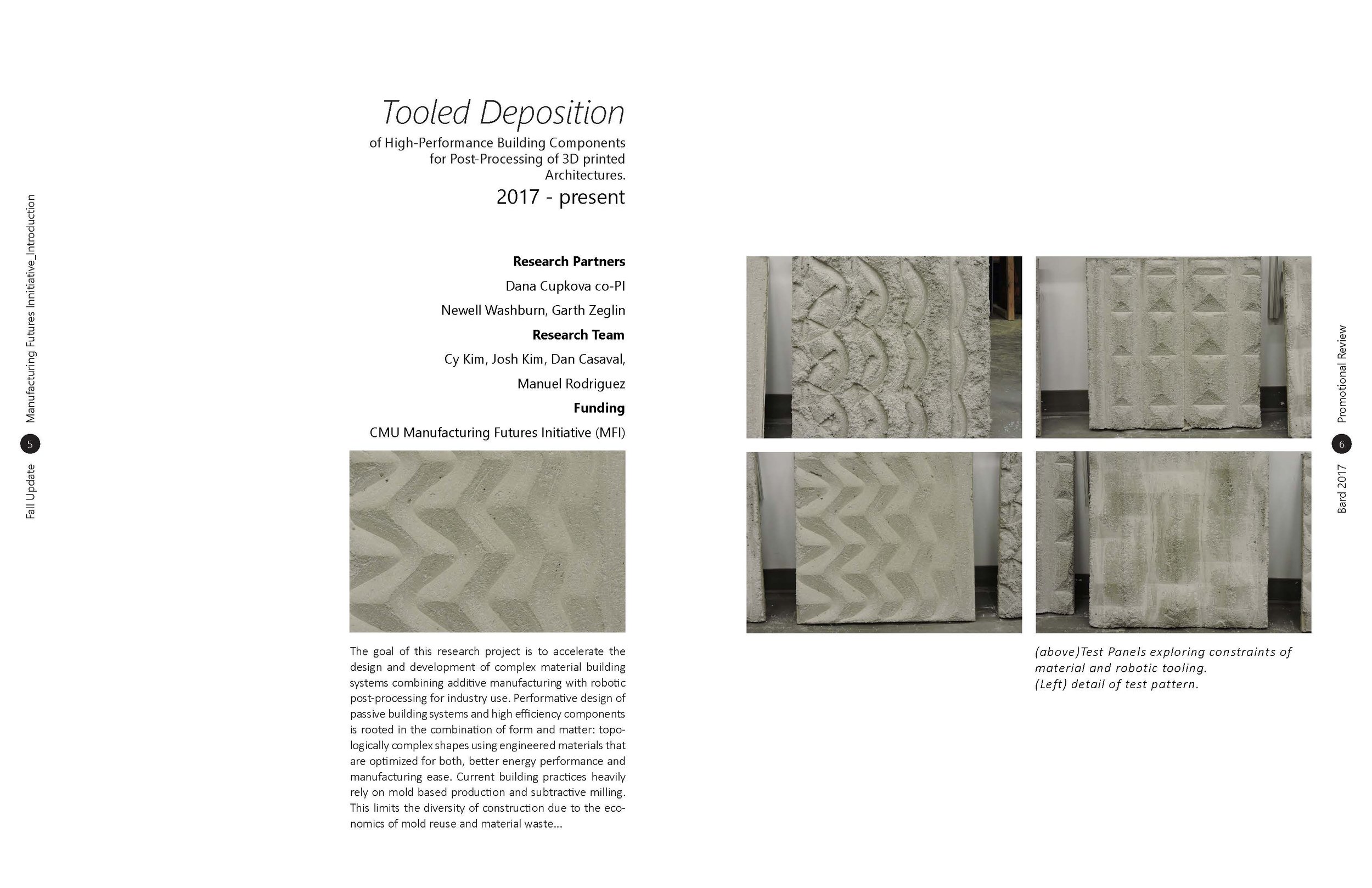

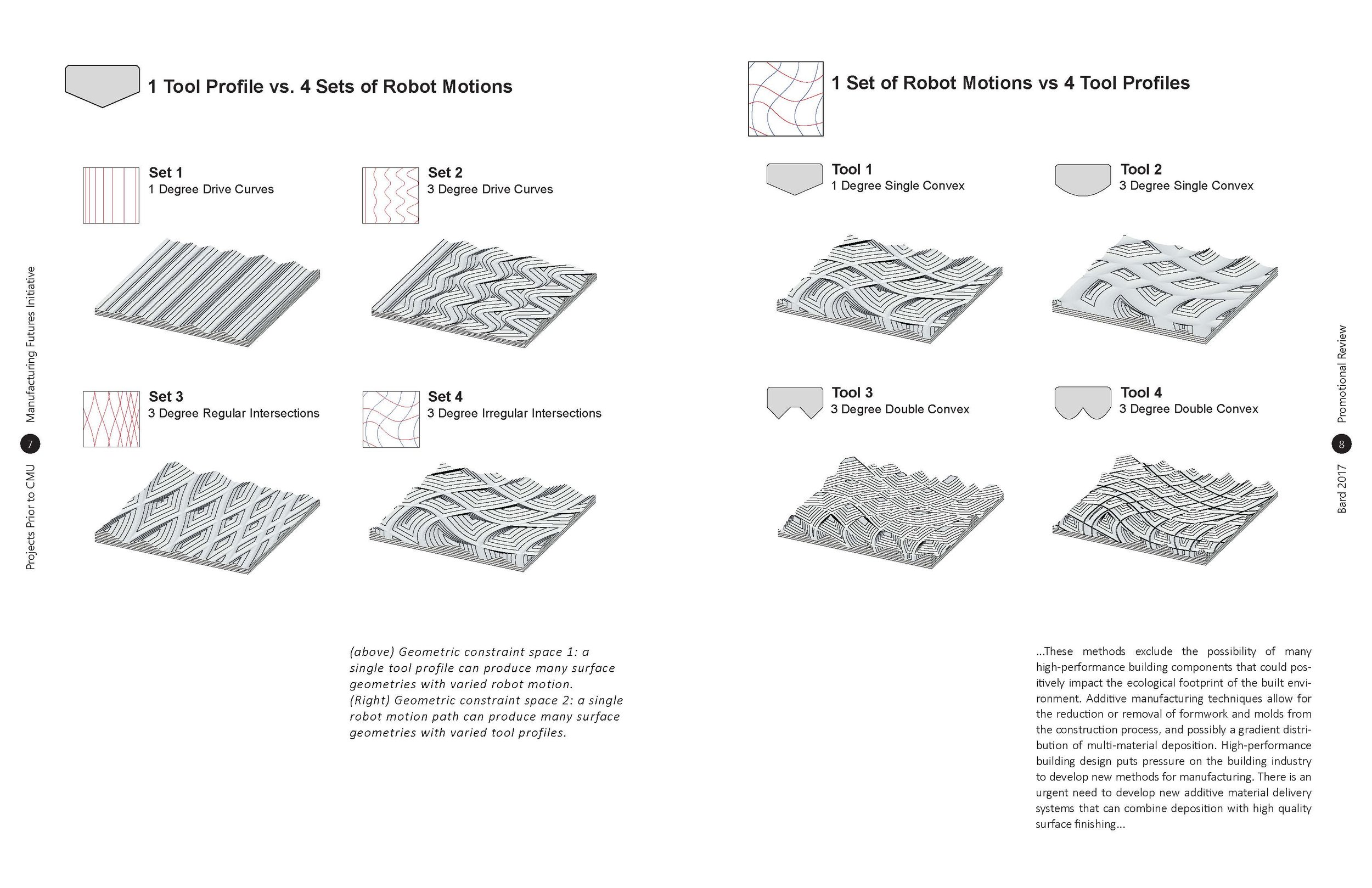

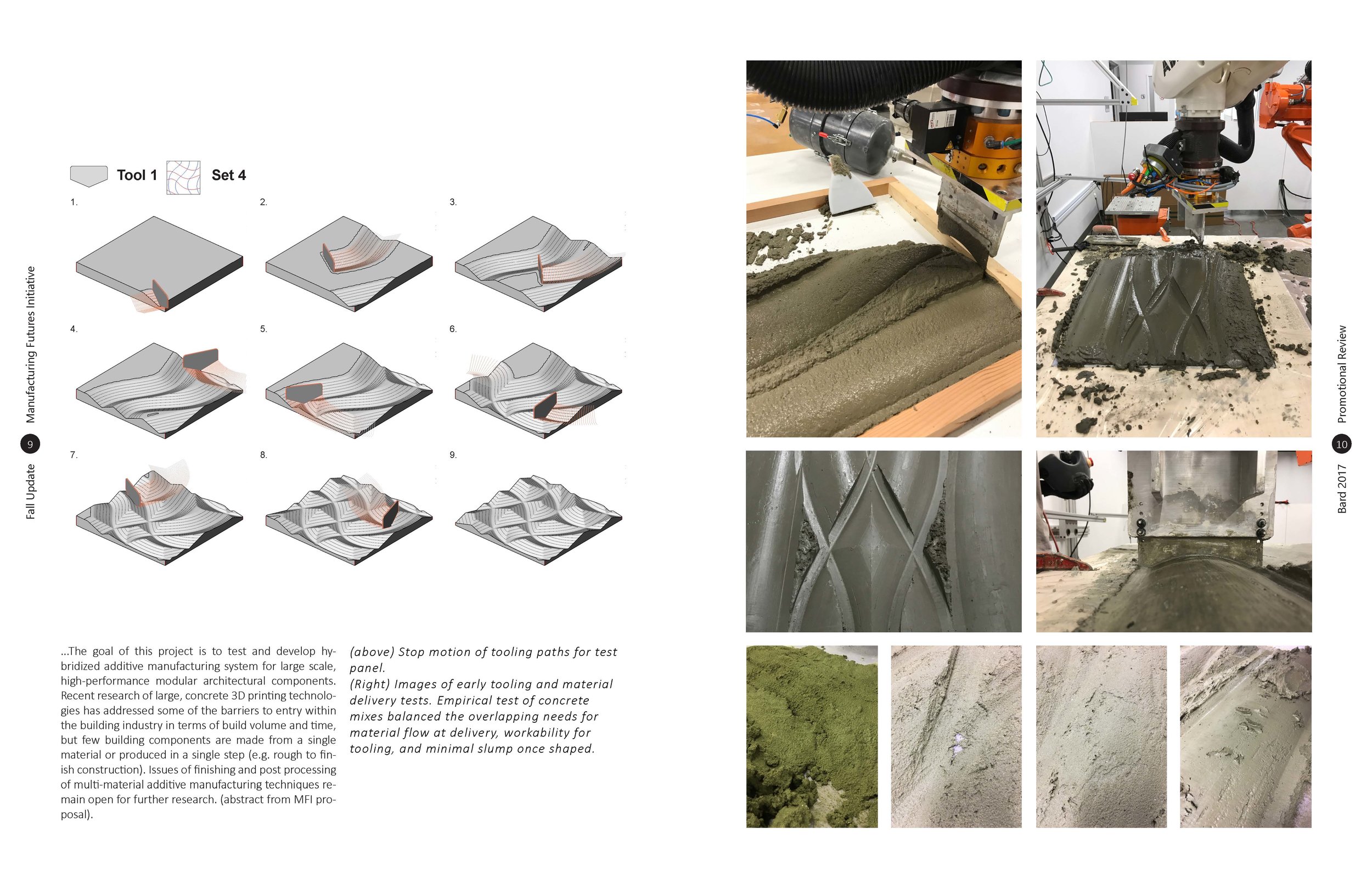

This ongoing project explores the intersection of the design and construction of high-performance building components that use complex geometry for actuating specific thermal behaviors. Using computation we combine simulation feedback, advanced modeling, and emerging robotic manufacturing techniques to create a seamless flow between design, evaluating thermal performance, and manufacturing. The project presents a novel approach to the production of concrete facade panels with complex surface geometries, combining additive manufacturing with tooled post-processing to achieve thermally performative surface definition. The robotic workflow developed for this project includes automated delivery of material for selective deposition of panel geometry, and tooled shaping of rough and finish layers for high-fidelity physical production of computationally generated forms.

form studies

other potential iterations

fabrication animation

tile samples

Fabrication Process

NEXT STEP: CONCRETE DEPOSITION MECHANISM (ONGOING)

EOAT

CONCRETE DELIVERY SYSTEM